- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 90 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

Terminal blocks (also called terminal connectors or connection terminals) are modular, insulated devices that join electrical wires securely without soldering. These electronic components are served as organized, reusable connection points—transforming chaotic wiring into structured systems. But their impact extends far beyond tidiness: they enable safety, scalability, reliable and resilience in everything from industry systems to solar farms. Let’s analyse their engineering and explore their critical industrial roles.

Terminal blocks use mechanical clamping mechanisms to create gas-tight, vibration-proof connections. Three dominant technologies dominate modern applications.Screw Clamps: A metal plate tightened by a screw grips wires (Connect well’s CTS series). Ideal for high-torque industrial use.Spring Clamps: Tension-based, tool-free connections (Phoenix Contact’s XBPT series) that resist vibration in moving machinery .Insulation Displacement Connectors: Pierce wire insulation for rapid, gas-tight joins , common in automation systems .

The second point: Why engineers prefer them rather than direct wiring

Safety: Flame-retardant housings (UL 94V-0 poly) prevent fires .

Housing : PA66 material is environment -protected usually . more safe.

Maintainability: Test points and plug-in bridges simplify diagnostics (XB Series’ standardized testing shafts) .

Installation: save your much time to install ,and it’s convenient for connecting and disconnecting ,

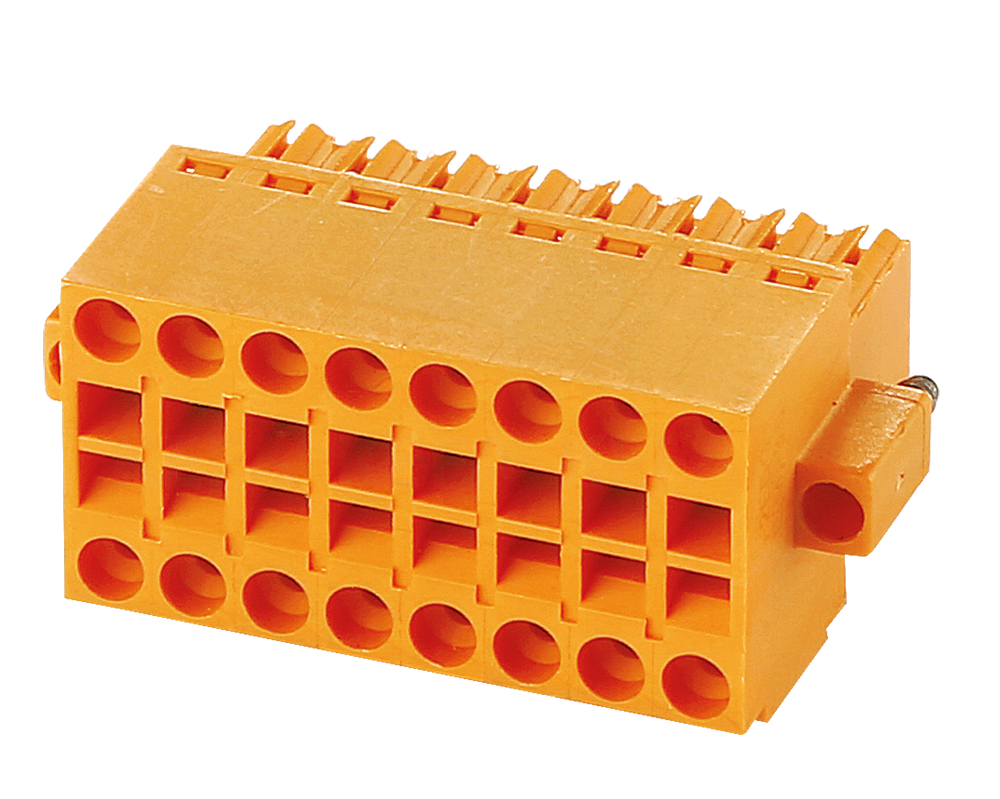

Density: Multi-level blocks (Connect well’s CTL2.5UH) triple connection capacity in tight spaces .

Control panels manage motors, PLC, and sensors in factories. Terminal blocks like KEFA ’s KFPDA2.5 organize high-current (≤57A) power distribution and I/O signals while withstanding temperatures from -40°C to +125°C. Double-layer DIN rail blocks save 40% panel space—critical in crowded cabinets. Features like color-coded markers and test plugs slash troubleshooting time during breakdowns.

Vehicles demand connections that survive vibration, heat, and corrosion. Spring-clamp blocks (WAGO series) lock wires with constant pressure, passing IEC 60068-2-6 vibration tests . Safety-critical systems like airbags use dedicated yellow terminal blocks with shorting pins—automatically grounding circuits during maintenance to prevent accidental deployment .

Solar junction boxes face extreme conditions: UV exposure, moisture, and DC arcing risks. Here, halogen-free thermoplastic blocks (IP55-rated) like SOLAR 2K12 handle up to 22A per string . Nickel-plated copper conductors resist electrolytic corrosion, while flame-retardant shells (UL 94V-0) contain overheating—key for rooftop fire safety .

HVAC units expose terminals to condensation, temperature swings, and compressor vibrations. Blocks like XBUT6 use tin-plated copper alloys to prevent rust, supporting 50A loads for compressors . Double-insulated designs prevent shorts in humid environments, while push-in connectors simplify field servicing in cramped units .

DIN rail-mounted blocks (Phoenix Contact PLC RPT) modular PLC installations. Rail blocks enable plug-and-play I/O expansion—critical for smart factories. ABB AC 900F controllers use triple-level blocks like CTL2.5UH to segregate signals, power, and grounding on one rail, accelerating panel builds by 30% .

4 key points for Choosing the Right Terminal Block

Electrical Load:Low-current sensors: IDC blocks (≤22AWG) .

High-power motors: Screw clamps (≥35mm² wire) .

Environment:Outdoor solar/HVAC: IP55+ sealing and UV-resistant shells .

Automotive/industrial: Vibration-proof spring clamps .

Space Constraints:

Compact panels: Double/triple-layer DIN rail blocks .

Maintenance Needs:Test points and plug-in bridges (XB Series) for diagnostics

Why use terminal blocks instead of wire nuts?

Terminal blocks allow reusable connections more and more convenient, comply with UL/CE/ROHS/CQC/VDE safety standards, and prevent loose wires in high-vibration settings like automotive harnesses or industrial robots .

Can terminal blocks handle 100A industrial loads?

Of course,Yes. Feed-through blocks like XBUT6,KF57S/KF67S/KF77S/KF89, support up to 57A continuously, while fused blocks manage over current in power distribution .

How do I secure terminal blocks in panels?

90% use DIN rails (TS35 standard). Spring-loaded clips snap blocks onto rails—no tools needed .

Are there explosion-proof options?

Yes. Connectwell’s Ex/IECEx-certified blocks (ODL2.5(I.S)) are approved for hazardous areas like chemical plants .

What’s the lifespan of a terminal block?

High Quality terminal blocks (Phoenix Contact,Wago connector, TE Connectivity,KF Terminal block) endure 100+ insertion cycles. Copper-tin alloys prevent fretting corrosion in HVAC systems .

The Future: Smarter Connections

Terminal blocks are evolving beyond passive connectors. Innovations like electronic-fused blocks (CTL2.5UL with built-in diodes) and smart markers (XB Series’ laser engravable tags) align with Industry 4.0’s demand for diagnosable, modular systems . As renewable energy and automation grow, these unsung heroes will continue enabling safer, denser, and more adaptable electrical infrastructures.

Tip: For mission-critical applications (solar farms or PLC), prioritize blocks with third-party certifications (UL, IEC Ex,ROHS) and matched accessories like bridges/test plugs—compatibility ensures system integrity.Shanghai Shanye Electronics Co;Ltd is professinal for supplying various of terminal blocks ,any need ,you can contact us free ! www.cnsyelectronics.com

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected