- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 79 Author: Site Editor Publish Time: 2023-05-29 Origin: Site

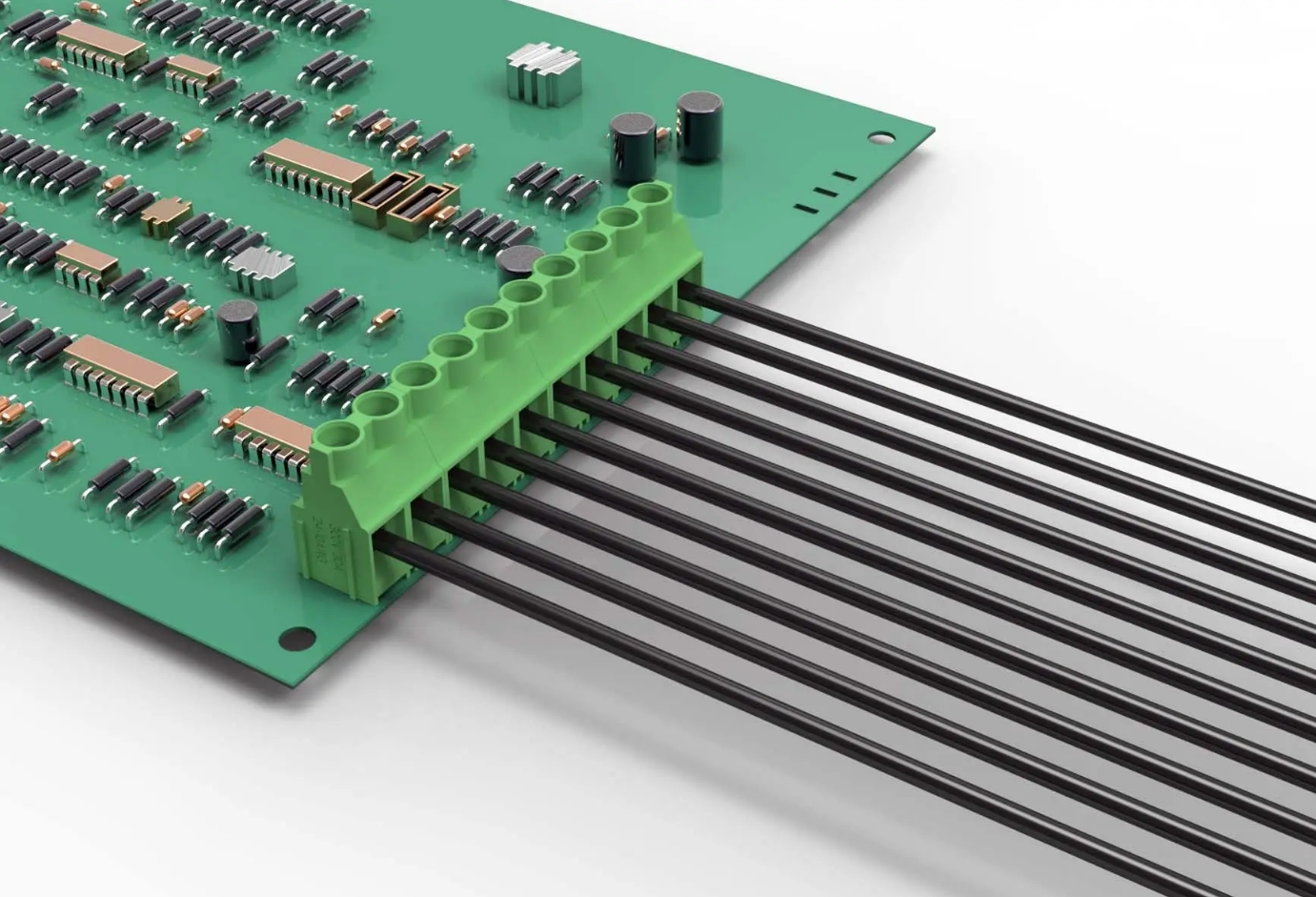

Surface-mount technology (SMT) wiring terminals are an essential component in electronic devices, as they provide a reliable and efficient connection between circuit boards, wires, and other electronic components. Choosing the right type of SMT wiring terminal is crucial for ensuring the proper functioning and long-term durability of electronic devices.

Application requirements: The first step in choosing the right SMT wiring terminal is to understand the application requirements. Factors such as current rating, voltage rating, temperature range, and environmental conditions such as moisture, dust, and vibration can influence the selection of the appropriate terminal.

Type of wire: The type of wire that will be connected to the terminal is another important factor to consider. The terminal should be compatible with the size and type of wire being used. It's also important to consider the insulation material and thickness of the wire, as this can affect the size and shape of the terminal required.

Termination method: There are several different termination methods for SMT wiring terminals, including through-hole, surface-mount, and press-fit. The termination method chosen will depend on the specific requirements of the application, such as the size and shape of the circuit board or the available space for the terminal.

Contact type: SMT wiring terminals are available in several different contact types, including spring-loaded, screw-type, and insulation displacement. The contact type chosen will depend on factors such as the type of wire being used, the current rating required, and the level of vibration and shock that the terminal will be subjected to.

Material: The material of the terminal can also influence the selection process. Common materials for SMT wiring terminals include copper alloy, brass, and phosphor bronze. The material chosen will depend on factors such as the level of corrosion resistance required and the temperature range the terminal will be exposed to.

Size and shape: The size and shape of the terminal will also be an important consideration. The terminal should be small enough to fit onto the circuit board or device, while also providing enough surface area for a reliable connection.

Brand and supplier: It's also important to consider the brand and supplier of the SMT wiring terminal. Choosing a reputable supplier that provides high-quality products can help ensure that the terminal will perform reliably and meet the necessary requirements for the application.

In conclusion, choosing the right SMT wiring terminal requires careful consideration of a variety of factors, including application requirements, wire type, termination method, contact type, material, size and shape, and supplier. By carefully evaluating these factors, electronic device designers and manufacturers can select the appropriate terminal for their specific application, ensuring reliable performance and long-term durability.

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected