- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 98 Author: Site Editor Publish Time: 2025-07-14 Origin: Site

Spring terminal blocks—revolutionary connectors that replace screws with spring force—have transformed electrical installations since WAGO launched the first cage clamp design in 1977. Originally selling 30,000 units in their debut batch, these components now underpin critical infrastructure worldwide, from high-speed trains to smart buildings. Here’s what every engineer should know.https://example.com/terminal-block-image.jpg

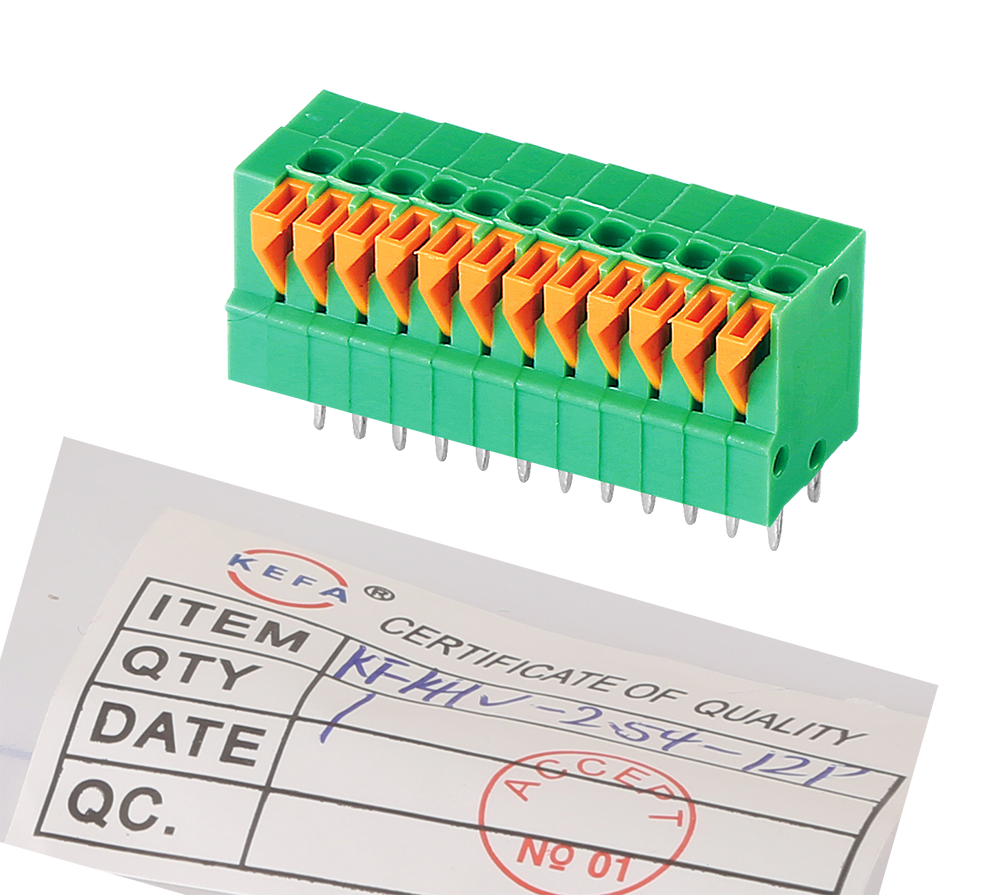

Figure: Evolution of spring terminal blocks, from early cage clamps to modern PCB-mounted designs.

Today’s designs like Phoenix Contact spring terminal block variants support currents up to 300A and wire gauges from 0.25 mm² to 95 mm². Shanghai Shanye Electronics Co;Ltd (KEFA ELECTRONICS’S branch)was established in 2017 years, which support wire gauges from 0.25 mm²~16 mm²(or24-10 AWG),Spring life up to 50-100 times operation!

Spring terminal blocks fall into four functional categories:

Type | Pitch/Spacing | Current Rating | Key Applications |

PCB Spring Terminal Block | 2.54mm–7.62mm | 5A–20A | Control boards, sensors |

Spring Cage Terminal Block (Rail) | 5.0mm/5.08mm | 20A–76A | Industrial cabinets, DIN rail systems |

Micro | ≤2.54mm | <5A | IoT devices, wearables |

High-Power | ≥10mm | 76A–200A | Energy distribution, drives |

Low-profile PCB terminals with 9mm stripping length, UL94 V-0 flame-retardant housing

Correct installation prevents 90% of spring terminal failures. Follow this procedure:Step 1: Preparation

Use wire strippers (not knives) to avoid conductor damage. Select terminal block spring type matched to wire gauge.Step 2: Strip Length

Exact length is critical—9–10mm for 281-681 terminals. Underexposure causes weak clamping; overexposure risks short circuits.Step 3: Insertion

For spring terminal block connector types:Lever-actuated: Open lever → insert wire → close lever,Push-In: Directly insert pre-stripped wire until “click” (no tools),Step 4: Verification

Tug-test wires (≥20N pull force). Use multimeters to check contact resistance (<5mΩ recommended).Critical mistake: Forcing oversized wires (16mm² into 6–35mm² terminals) causes overheating.

Domestic Leaders:WAGO (Tianjin): 1,600+ employees, supplies China’s high-speed rail with vibration-proof terminal block spring loaded units,KEFA ELECTRONICS: Claims 50% faster wiring than screw terminals, with IEC 60947 compliance,Shanghai Shanye Electronics: Specializes in PCB spring terminal block for lighting/communication systems

International Brands:Phoenix Contact: High-density solutions for Industry 4.0,WAGO Germany: Pioneered spring cage terminal block tech; dominates EU rail markets

Rail Transport: Mandated in Chinese high-speed trains (for ≤6mm² wires) due to vibration resistance. Used in doors, signals, and track heating at -50°C–120°C.Energy/Industrial: Shanye’s spring clamp din rail terminal block simplifies panel building 50% faster

Building Automation: WAGO’s 221 series connects HVAC/lighting via IP20/IP67 units,Consumer Electronics: PCB spring terminal block in LED drivers (ceiling light control boards)

6. Why Engineers Choose Spring Terminals? Advantages:

Safety: PA66 housings (UL94 V-0) prevent fires; stainless springs resist corrosion,Reliability: Maintain contact force under vibration—critical for trains/motors

Efficiency: Install wires 80% faster vs screws; cuts labor time by 50%,Versatility: Accept stranded/solid wires (0.08mm²–16mm²) without lugs

Overheating/Melting:

Cause: Wrong wire size (16mm² in 6–35mm² terminal) or undersized terminals

Fix: Verify cross-section compatibility; use torque testers on production lines,Intermittent Failure:

Cause: Incomplete insertion or insulation under clamp

Fix: Inspect strip length; use transparent-housing terminals

Spring Fatigue:

Cause: Excessive re-wiring (beyond 10 cycles for economy models)

Fix: Specify high-cycle variants ( WAGO’s 100,000-operation designs)

Metric | Chinese Brands | Imported (WAGO/Phoenix) |

Cost | 30–50% lower | Premium pricing |

Temperature Range | -40°C to 105°C | -60°C to 120°C |

Cycle Life | 50–100 operations | 100–500+ operations |

Certifications | GB/T, IEC | UL, ATEX, IRIS (rail) |

Implication: Imported units lead in extreme environments (-50°C Tibetan railways), but domestic suffice for commercial use. |

Q: Can spring terminals handle 18AWG stranded wire?

A: Yes—most accept 22–14AWG. Use ferrules if strand dispersion occurs.

Q: Why did my terminal block melt in a lighting panel?

A: Likely overcurrent or loose contact. Check ampacity ( 20A max for 5mm² models) and measure contact resistance post-install.

Q: Are there waterproof spring terminal blocks?

A: Yes—IP67-rated spring type terminal block units (WAGO 273 series) for outdoor use. Shanye’s Heavy duty connectors can suit your requests.

Q: Do I need special tools for push-in terminals?

A: Only for removal—a 2.5mm release tool. Insertion is tool-free

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected