- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 98 Author: Site Editor Publish Time: 2025-07-11 Origin: Site

The electric vehicle (EV) charging landscape is surging, driven by global decarbonization goals and unprecedented consumer adoption. While flashy EV models grab headlines, the true backbone of this revolution lies in the robust hardware enabling reliable, ultra-fast charging—especially within the charging station itself. At the heart of these critical power pathways sit specialized terminal blocks for EV chargers, components whose performance dictates everything from uptime to safety. As currents soar beyond 500A and voltages push past 1000VDC in next-gen 350kW+ chargers, conventional connection solutions falter. Here’s how advanced terminal blocks are engineering the future.

The Relentless Demands on Modern EVSE

EV charging equipment (EVSE) operates in punishing conditions:Extreme Electrical Loads: DC fast chargers (DCFC) now deliver 150-350kW, requiring continuous currents of 300A-500A+ per module. This generates intense thermal stress.Harsh Environments: Public charging stations face moisture, dust, temperature swings (-40°C to +85°C), and mechanical vibration—particularly in mobile or trailer-mounted units.Critical Safety Mandates: Arcing, insulation failure, or contact corrosion can trigger fires or electrocution risks, demanding UL94 V-0 flame-retardant materials and reinforced isolation.Maintenance Complexity: Technicians servicing live 1000VDC systems need intuitive, error-proof designs to prevent accidental contact.

ShanYe’s Solutions: Engineered for Electrification’s Edge can help you save 30% cost ! High-current terminal blocks and Spring terminals is our mainly products ,and be populared in more than 50 countries .

1. Conquering Kilowatts: High-Current Pathfinders

1. Conquering Kilowatts: High-Current Pathfinders

For the core power highways in 350kW+ EV chargers, 500A high-current screw terminal blocks are indispensable. These terminals feature:Thick copper alloy conductors with low millivolt drop, minimizing heat buildup even at 500A continuous loads.Dual-pressure cage clamps securing cables up to 95mm², preventing creep under thermal cycling.UL94 V-0 rated terminal blocks for electric bus charging stations, ensuring ignition resistance in high-energy fault scenarios.2. Sealing Out Disaster: The IP67 Imperative

Outdoor charging stations demand complete immunity to dust and water immersion. IP67 terminal blocks for charging stations achieve this via:Silicone-sealed housings and compression gaskets that repel moisture even during high-pressure washdowns.Corrosion-resistant alloys and contacts, critical in coastal or de-icing chemical environments.Integration proven in heavy vehicle and solar applications, where environmental resilience is non-negotiable.

3. Smarter Signal Integrity: Precision Meets Reliability

Battery Management System (BMS) communication errors can derail charging sessions. High-tensile spring terminals with silver-plated contacts for BMS signal wiring deliver fault-free low-voltage control:Silver-plated contacts maintain stable resistance (<5mΩ) for CAN bus, PLC, or Ethernet signals.Spring pressure remains constant over 10,000+ mating cycles, eliminating loose connections that cause data glitches.Integrated test points enable diagnostics without disassembly.4. Taming Tremors: Vibration-Proof Power Transfer

Mobile charging trailers and depot chargers endure constant shaking. Thread-locking busbar terminals for anti-vibration in mobile EV charging trailers lock connections solid with:Serrated washers and thread-locking adhesives that resist loosening under ASTM D999 vibration profiles.Electrodeposited busbars distributing up to 1000VDC without hotspot risks.Modular DIN-rail mountable high-current terminals with test points for EVSE diagnostics, enabling quick field swaps.5. Safety by Design: Preventing Human Error

Maintenance mistakes in public chargers can be lethal. Color-coded barrier terminal blocks for safe maintenance of public charging stations enforce safety through:Brightly segmented barriers isolating 1000VDC/500A lines from low-voltage circuits.Touch-safe finger guards meeting IPXXB standards, shielding live parts during servicing.

6. Scaling Tomorrow’s Grid: The Modular Advantage

DCFC networks must scale rapidly. Plug-and-play terminal blocks for modular DC fast charger expansions cut deployment time by 40% with:Blind-mate power and data connectors enabling tool-less cabinet expansions.Pre-assembled harnesses integrating spring terminals for EVSE power stages, slashing field wiring errors.

The Future Is Terminated Securely

As 800V architectures and megawatt charging (MCS) emerge, terminal blocks will face even starker tests. ShangYe is pioneering liquid-cooled terminal designs and solid-state contact monitoring to meet these frontiers. One truth remains: in the race to electrify transport, every kilowatt flows through a terminal. Choosing blocks engineered for the crucible of EV charging isn’t just technical—it’s existential.

ShanYe Electronics: Powering Connections That Drive The Future,If you need to get more ,pls visit our website :www.cnsyelectronics.com, we are in service 24 hours for you !

Explore our EVSE Terminal Solutions Catalog →

Keywords: High-current terminal blocks for EV chargers, IP67 terminal blocks for charging stations, Spring terminals for EVSE (Electric Vehicle Supply Equipment), Busbar terminals for DC fast chargers, 500A high-current screw terminal blocks for 350kW EV chargers, 1000VDC UL94 V-0 rated terminal blocks for electric bus charging stations, High-tensile spring terminals with silver-plated contacts for BMS signal wiring, Thread-locking busbar terminals for anti-vibration in mobile EV charging trailers, DIN-rail mountable high-current terminals with test points for EVSE diagnostics, Color-coded barrier terminal blocks for safe maintenance of public charging stations, Plug-and-play terminal blocks for modular DC fast charger expansions.

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

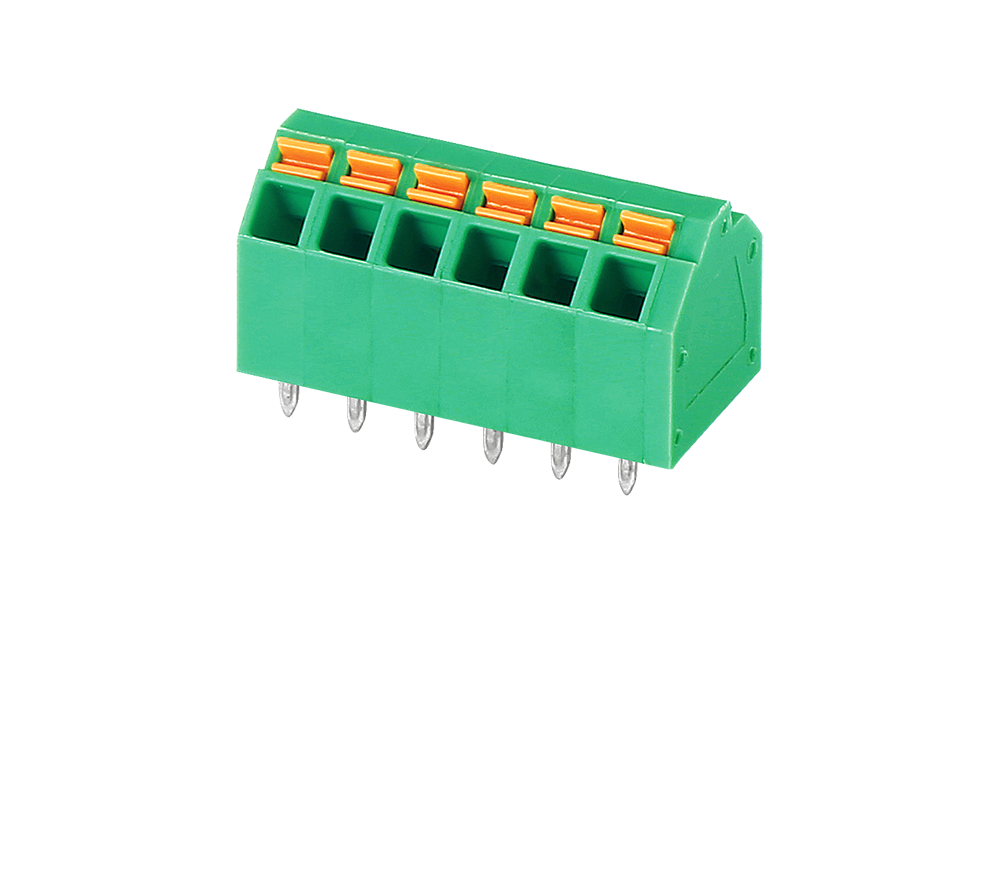

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected