- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 85 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6 billion global terminal block market through continuous innovation in electrical connectivity solutions.

Why to Choose the best Terminal Block

Although Top brand recognition matters when selecting terminal blocks, but true value lies in proven performance. you need suppliers demonstrating certified reliability, engineered safety, continuous innovation, responsive technical support . certification(UL/VDE/ROHS/SGS/ISO14001/ISO9001/ICE/IEC),Material traceability and testing documentation,Global technical service networks,Transparent performance data across temperature ranges,Choosing established manufacturers represents more than component selection - it's your primary safeguard against operational failures and maintenance costs. Premium terminal blocks deliver measurable ROI through reduced failure rates and extended service life, ensuring your electrical systems perform as designed when reliability matters most.

Testing Methods Used by Top Terminal Block Brands

Test Type | Standard | Purpose / Evaluation Criteria |

Aging Test | IEC 60947-7-1/-2 | Evaluate long-term contact quality and durability |

Fire Safety | EN 45545-2 | Ensure material fire safety compliance |

Flammability | UL 94 | Assess plastic flame resistance |

Climate Test (Dry Heat) | IEC 60068-2-2 | Performance verification under high temperatures |

Corrosion Test | DIN 50018 | Check corrosion resistance |

Salt Spray Test | IEC 60068-2-11/-52 | Simulate marine environment conditions |

Tracking Resistance | IEC 60112 | Measure comparative tracking index (CTI) |

| Glow-Wire TestIEC 60695-2-11Simulate heat from overloaded conductors

| Glow-Wire TestIEC 60695-2-11Simulate heat from overloaded conductors

| Glow-Wire TestIEC 60695-2-11Simulate heat from overloaded conductors

|

Top Brand Terminal Block features

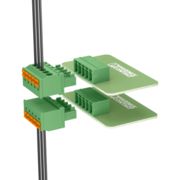

Phoenix Contact: An Innovative and Trusted Leader.As a pioneering German company, Phoenix Contact leverages smart Industry 4.0 technologies to make wiring faster, simpler, and error-free. Their push-in connection technology requires no tools — simply insert the wire for a secure and reliable connection. This not only saves time but also significantly reduces installation errors.Phoenix Contact offers a robust product portfolio including the COMBICON, QUINT, and PLUSCON series. The Push-X series, featuring spring-loaded mechanisms, enables even faster wiring.These products excel in control cabinet and automation system applications.Safety remains a top priority. The company’s TÜV-certified solutions help prevent failures and protect sensitive data. Should you need support, their expert team and digital services are always available.Choose Phoenix Contact for intelligent, safe, and sustainable electrical solutions.

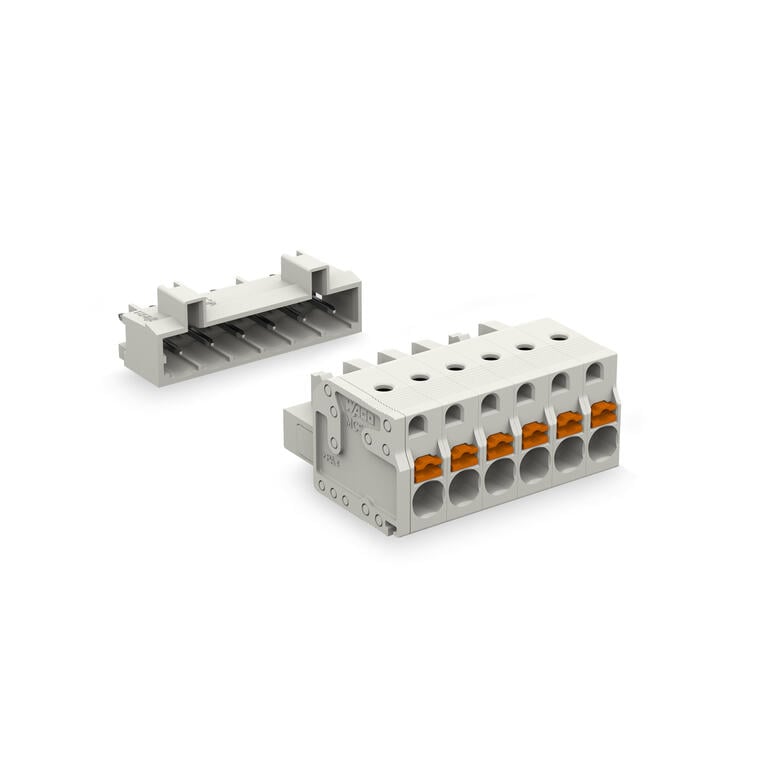

WAGO's terminal blocks enable easy, tool-free wiring through their innovative CAGE CLAMP® spring-pressure and lever-actuated designs – no screwdriver required. The audible "click" of the lever confirms a secure connection, effectively preventing vibration-induced loosening, high-temperature degradation, and corrosion-related failures.The compact TOPJOB® S series is ideal for confined spaces, available in both single and multi-level configurations. With the X-COM® S-SYSTEM, modules can be easily plugged and unplugged for flexible system integration. WAGO also manufactures miniaturized versions for small control panels, along with a full range of connectors for faster installation.

Eaton:The compact Bussmann TB200 series can be mounted directly on switchboards without requiring DIN rails. Multiple units can be combined to accommodate long circuits. The 8559 series features stackable design for flexible wiring arrangements.

Eaton’s terminal blocks are ideal for control panels and machinery, enabling efficient wiring even in tight spaces. If you need reliable terminal solutions for confined or crowded environments, Eaton offers a smart and practical choice.

With Molex, you can quickly connect and disconnect wires – no soldering required. Their terminal blocks help maintain organized wiring while delivering solid, reliable connections that prevent wire loosening.

Molex offers screw-type, spring-clamp, and cage-clamp terminal options, allowing easy wire insertion and removal. Built to withstand demanding conditions, these terminals provide long-lasting performance even in harsh environments.

Cost-effective and simple to maintain, Molex terminal blocks are the smart choice when you need flexible, robust, and user-friendly connectivity solutions.

As a global leader in connectivity solutions, Amphenol's terminal blocks are recognized for their exceptional performance and innovative engineering. Featuring high-density miniaturization (1.27mm pitch), these components save over 30% of PCB space while supporting current ratings from 10A to 250A, making them suitable for applications ranging from consumer electronics to industrial systems.

HARTING Heavy-Duty Connectors:Die-cast metal housings (zinc/aluminum alloy) or engineering plastic versions.Up to IP68/IP69K protection rating (dust/water resistant).Mechanical impact protection level IK08-IK10 (compliant with EN 62262).Hybrid transmission capability: power (up to 125A), signal, data, coaxial, and fiber optics.Three termination methods: crimping, screw, or spring clamp.Shielding effectiveness >90 dB (meets EN 61076-2 EMC standard)

Safety and reliability features:High-voltage interlock loop design (suitable for electric vehicles/industrial safety).Anti-mismating coding system.certification .

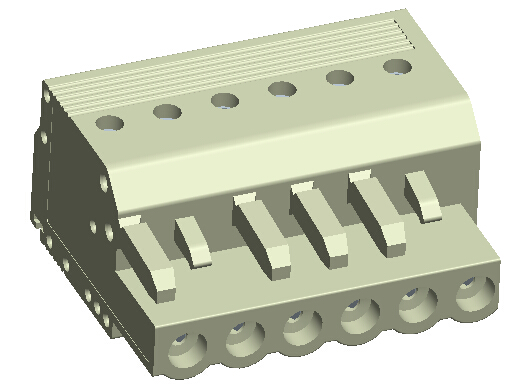

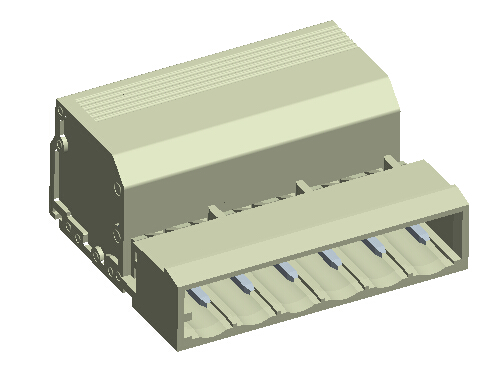

Shanye Electronics offers a wide range of terminal block solutions, including wire-to-wire plug-in, barrier, feed-through, screw-type, and tool-free types. Their terminal blocks are constructed with high-strength materials suitable for high-temperature environments.

Lift-type clamping and spring cage technologies enable fast and secure wiring. These products are widely used in power systems, control panels, PCB assembly, EMS assembly, servo drive control, HVAC systems, and more.

The spring cage technology combines push-in convenience with spring-loaded reliability, delivering compact, modular, and easy-to-install solutions for cost-effective connections. We can supply 3D service in shortest time ! if you have any need !

If you seek quality, diverse options, and economical pricing, Shanye Electronics is your ideal choice.

Brand | Reliability & Safety | Innovation Highlights | Application Suitability |

Phoenix Contact | Vibration resistance and heat tolerance | Revolutionary pluggable connection | Industrial control |

WAGO | Vibration-proof spring clamp | Patented CAGE CLAMP™ | Automation |

Weidmüller | Comprehensive testing | German engineering | Custom solutions for automation and transportation |

Eaton | Space-saving stackable design | Flexible wiring solutions | Control panels |

Amphenol | • UL/ICE/IEC Certified • High-temperature LCP Materials • Corrosion-resistant Plating • Vibration-resistant Contacts | • Miniaturized Designs • Mixed-power Configurations • IDC Insulation Displacement • EMI/RFI Shielding | • Automotive Electronics • 5G Infrastructure • Industrial Robotics • Medical Equipment |

Harting | • IP65/68/69K Rated • Heavy-duty Metal Housings • Shock/Vibration Certified • Hazardous Environment Approval | • PushPull Locking System • Modular Contact Inserts • Han® Configurator Tool • Hybrid Data/Power Modules | • Railway Systems • Offshore Wind Farms • Factory Automation • Mobile Machinery |

Shanye Electronics | • UL 94 V0 & RoHS Compliant Materials • Antivibration Spring Clamp Design • Secure Lifttype Clamping Mechanism • Clear Marking for Errorfree Wiring | • Pushin Spring Cage Technology • Modular & Compact Structure • Integrated Test Points • Costeffective Customization | • Industrial Control Cabinets • HVAC & Power Systems • PCB & EMS Assembly • Servo Drive & Automation |

Kefa Electronics | • Full IEC 6094771 Certification • Enhanced CTI Tracking Resistance • Robust PA66 Housing • Temperature Range -25 ℃ ~ +105 ℃ | • Miniaturized Terminal Series • Multilevel Stackable Design • Springassisted Screw Clamping • Rapidmount DIN Rail Options | • Consumer Appliances • Lighting & Building Wiring • Renewable Energy Auxiliary Circuits • Industrial Machinery |

Why Do We Use Terminal Blocks?

Terminal blocks serve as critical electronic components in electrical installations, providing tangible benefits that go beyond basic wire connections. Here's why professionals specify them

1. Maintenance Efficiency

Disconnect individual circuits without cutting wires

Transparent housings reveal contact conditions.Integrated test points enable voltage/current measurements

2. Enhanced Safety Compliance.Spring-clamp and screw-type mechanisms prevent vibration-induced loosening. Isolate high-voltage (up to 1000V) and low-voltage circuits in same enclosure. IP67-68 rated blocks resist dust, moisture, and chemical exposure

3. Cost Reduction.Spring-cage terminals reduce wiring time by 60-70% versus direct connections.Push-in designs require only basic strip tools.Reconfigure systems without replacing components

4. Harsh Environment Performance

Maintain connection integrity in industrial/transport applications. Operate from -40°C to +125°C (specialty versions to 150°C).Tin/silver-plated copper contacts withstand humid atmospheres

5. Space Optimization

5.08mm-3.5mm pitch designs maximize panel space utilization.Vertical configuration minimizes footprint. Modular expansion without redesign

6. Design Flexibility Combine power, signal, and data transmission in unified assemblies.Create complex circuit routines with jumper configurationsLaser-marked surfaces ensure accurate circuit tracing.Facilities implementing terminal block systems report 45% faster installation timelines and 80% reduction in connection-related failures. The modular nature enables rapid equipment modifications while maintaining code compliance across industrial, commercial, and residential applications.Terminal blocks represent not just connection points but systematic solutions for creating maintainable, safe, and adaptable electrical infrastructures that scale with technological demands.

Projected CAGR: 5.8%-6.5% (2024-2029)

Market Value: Growth from $4.6B (2023) to $6.5-6.8B (2029)

Industrial Automation

Industry 4.0 adoption boosting PLC and robotics demand (+7.2% annually)

High-density terminal block requirements in smart factories up 40%

New Energy Expansion

EV charging infrastructure: terminal block demand growing 12.5% yearly

Solar/energy storage: corrosion-resistant, high-current blocks up 9.8%

Infrastructure Investment

Global grid modernization (smart meter terminals +8.3%)

Asia-Pacific rail transit (vibration-resistant terminals +11.2%)

Asia-Pacific Dominance (58% share)

China: New energy + automation (+8.1% annually)

India: Infrastructure investments (+10.5%)

European Transition (24% share)Automotive electrification: high-voltage terminals +13.8%

Industrial robot density increasing (12→18 per 10,000 workers)

North American Upgrade (16% share)

Grid modernization ($36B investment over 5 years)

Aerospace terminals (lightweight demand +6.9%)

Screw Terminals: Share declining from 45% to 38% (2029)

Spring/Push-in Terminals: Share increasing from 35% to 42% (2029)

Specialty Terminals (high-voltage/high-frequency): Share growing from 20% to 25% (2029)

Any other questions , you can see also

What’s The Differences between Push-in Terminals And Spring-loaded Terminals

How To Wire A Terminal Block Can Save Money And Time 30%

Why Do We Need Terminal Blocks

What Is The Difference of Terminal Electronics And Wiring Terminals

Do You Really Know What Is A PCB Terminal Block

How To Wire Terminal Block Connector in Different Fields

How Does Terminal Blocks Improve Circuit Safety

What is a Terminal Block in Electrical Engineering

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected