- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 73 Author: Site Editor Publish Time: 2023-10-31 Origin: Site

In industrial applications, heavy-duty connectors are used to provide power and signal connections between various equipment and devices. They are designed to withstand harsh environmental conditions, such as extreme temperatures, moisture, vibration, and impact. The selection of heavy-duty connectors is critical to ensure that the connections are secure and reliable in these challenging environments. One of the critical factors in selecting heavy-duty connectors is their Ingress Protection (IP) and National Electrical Manufacturers Association (NEMA) ratings.

IP ratings are defined by the International Electrotechnical Commission (IEC) and indicate the degree of protection against solids and liquids. The first digit in an IP rating indicates the level of protection against solids, while the second digit indicates the level of protection against liquids. The higher the number, the greater the protection. For example, an IP67 rating means that the connector is dust-tight and can withstand immersion in water up to one meter deep for up to 30 minutes.

NEMA ratings are defined by the National Electrical Manufacturers Association and indicate the level of protection against environmental hazards such as water, dust, and corrosion. The NEMA rating system is similar to the IP rating system but provides additional protection against corrosion and other hazards. The higher the NEMA rating, the greater the protection. For example, a NEMA 4X rating means that the connector is protected against dust, water, and corrosive agents.

When selecting heavy-duty connectors, it is important to consider the environment in which they will be used and choose connectors with appropriate IP and NEMA ratings. For example, connectors used in outdoor applications will require higher IP and NEMA ratings than those used in indoor applications. Similarly, connectors used in corrosive environments such as chemical plants will require higher NEMA ratings than those used in dry environments.

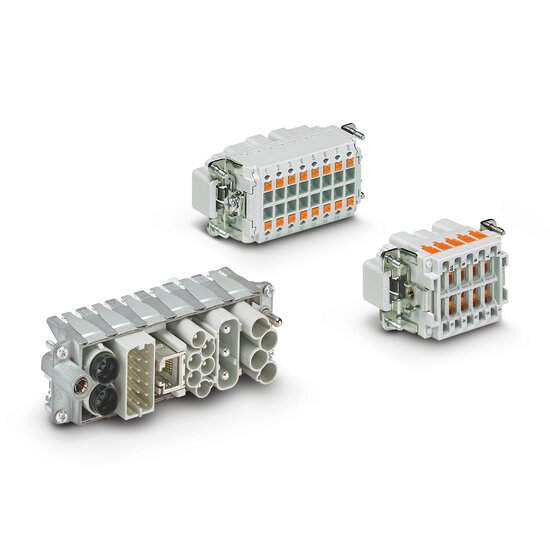

In addition to IP and NEMA ratings, it is important to consider the type of connector when selecting heavy-duty connectors. There are several types of heavy-duty connectors available, including circular connectors, rectangular connectors, and modular connectors. Circular connectors are typically used in applications where there is limited space, such as in aerospace and military applications. Rectangular connectors are more commonly used in industrial applications, where there is more space available for connectors. Modular connectors allow for flexibility in the number and type of connections and are often used in applications where the requirements may change over time.

Finally, it is important to consider the current and voltage requirements when selecting heavy-duty connectors. Heavy-duty connectors are available in a range of current and voltage ratings, and it is important to choose connectors that can handle the required current and voltage. It is also important to ensure that the connectors are compatible with the cables and wires being used, as well as the equipment and devices that they will be connected to.

In conclusion, selecting heavy-duty connectors based on IP and NEMA ratings is critical to ensuring that the connections are secure and reliable in harsh environments. It is also important to consider the type of connector, current and voltage requirements, and compatibility with cables, wires, equipment, and devices. By selecting the right heavy-duty connectors, industrial applications can benefit from improved reliability, reduced downtime, and increased safety.

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected