- All

- Product Name

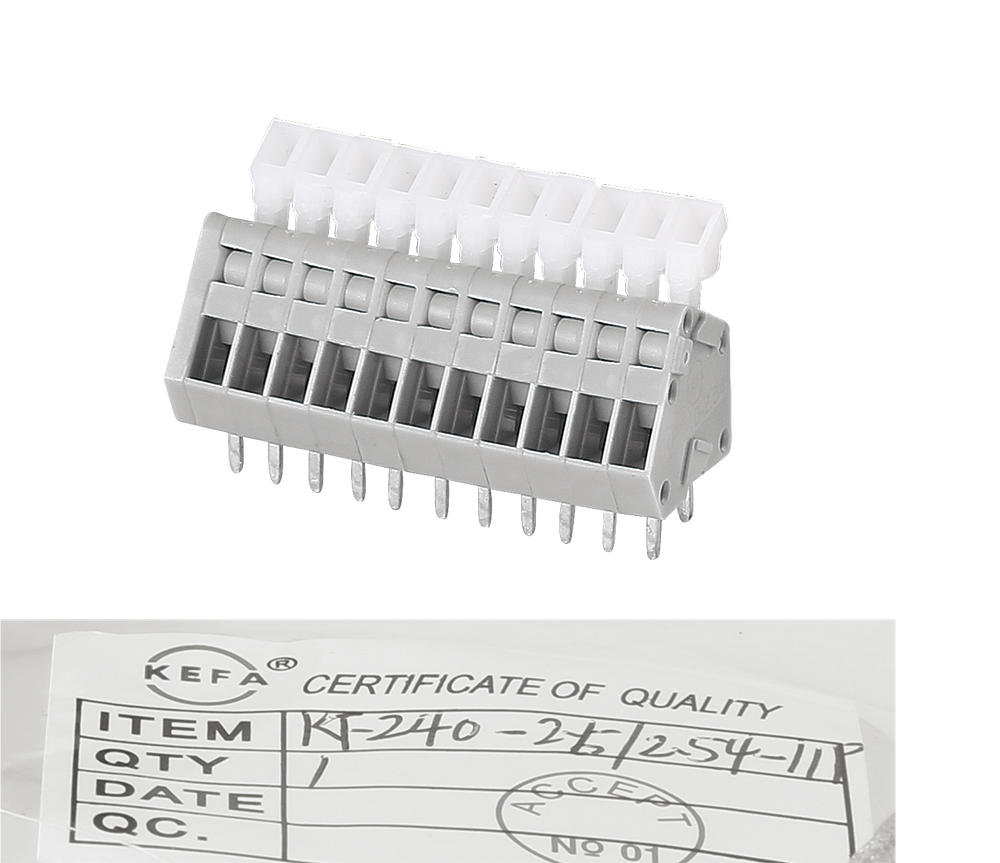

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 88 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market.

Spring terminal blocks provide a fast and reliable connection by using a spring mechanism to connect wires. When you place the wires in the spring part of the terminal block, they are automatically tightened. This feature allows easy insertion and removal of wires. Spring terminal blocks are widely used in industrial automation systems and control panels. The advantages of this type of terminal blocks include quick installation, reliability and ease of maintenance.

What types of spring terminal block?

Spring clamp PCB terminals use cage spring or V-spring connection technology, offering high vibration resistance. They can accommodate conductors with cross-sections ranging from 0.08 mm² to 16 mm², with pin spacings from 2.5 mm to 10.16 mm. These terminals can be used interchangeably with screw-type PCB terminals, providing greater flexibility. The product design complies with international standards such as IEC 60998, UL 1059, UL 486E, and CSA C22.2 No. 158.Common types include standard spring clamp terminals, fuse terminals, and test terminals.They are divided into low-current terminals and high-current terminals, from 3A to 150A ,each suitable for different current ranges.

They can connect various types of wires ranging from 0.08 mm² to 16 mm².

A variety of spacings are available, ranging from 2.5mm,2.54mm,3.5mm,5.0mm,5.08mm,7.5mm,7.62mm to 10.16 mm.Phoenix contact with so many years development ,supplyer variety of spring terminal blocks. such as power turn connection,T-LOX connection,SUNCLIX connection.With more and more domestic brand of spring terminal blocks rise sharply in recently years,Shanghai Shanye Electronics Co ,Ltd(KEFA ELECTRONICS’agent)have to be a special supplyer ,which supply competitive terminal block ,spring type terminal block, barrier type terminal block, pluggable terminal block, Din-Rail terminal block,feed through terminal block,etc. We can help you save 30% cost ,if you are interested in ,pls contact us freely !We can help you supply guides of model selection, if you need.

In spring-loaded terminals, often also referred to as cage terminals, the conductor is fixed in a retaining profile using a spring. The spring can be opened using a tool, which needs to be inserted into an operating slot. This allows both flexible conductors (with or without ferrules) and solid conductors to be connected. The spring provides the required contact pressure and prevents the conductor from slipping out. In contrast to screw terminals, this avoids issues with the terminal not operating correctly due to too much or too little torque being applied when tightening the screws. The connection is based on a self-locking mechanism and is thus mechanically durable and electrically safe. Even when exposed to vibrations and shocks, spring-loaded terminals do not loosen by themselves and there is no need for regular maintenance.

Push-in technology is a further development of spring-loaded terminals. As such, in a plug-in terminal the electrical contact is also made and the conductor fixed in place using a spring. However, in the case of push-in technology, the spring will open if the conductor itself is pushed in—this means that rigid conductors or conductors with ferrules can be directly connected without the need for any tools. In order to open the spring and to connect flexible conductors without ferrules, push-in terminals also feature a mechanism that can be operated using a standard screwdriver.

Push-in terminals offer the same advantages as spring-loaded technology: The clamping force does not depend on the user, thereby avoiding issues with the terminal not operating correctly. As with spring-loaded terminals, the conductor is inserted and actuated from the front, which enables compact device designs and simplifies handling.

The disadvantage of spring-loaded terminals is that they cannot be operated without tools; therefore you always need both hands to make the connection. This takes time and, with large cross-sections, a lot of effort, as in this case the terminals have to be forced open, which risks causing damage. If the wrong tool is used, for example a cross-head screwdriver, the spring can also be irreparably damaged. While a screwdriver that is too small will not open the connection completely, meaning that the specified nominal cross-section cannot be accommodated.

These problems are eliminated when using push-in terminals. As with spring-loaded terminals, the conductor is inserted and actuated from the front, which enables compact device designs and simplifies handling. However, the USP of push-in technology is that it enables the direct, tool-free insertion of conductors. The conductor can be inserted and connected with just one hand. This means even users with less technical knowledge can safely install push-in terminals. Practical tests show that wiring push-in terminals takes up to 40% less time compared to spring-loaded terminals.

As you can see from the table, push-in terminals offer significant advantages in speed and ease of use. As with spring-loaded terminals, the conductor is inserted and actuated from the front, which enables compact device designs and simplifies handling.

Feature Spring-Loaded Terminals Push-In Terminals

Tool Required | Always (screwdriver to open the clamp) | Only for stranded wires without ferrules |

Installation Speed | Slower (requires two-handed operation) | Up to 40% faster (true one-handed, tool-less operation for solid wires) |

Ease of Use | Requires some technique and correct tool | Extremely easy, less room for user error |

Best For | Applications where re-wiring/repositioning is frequent | High-volume installations, solid core wires, and maintenance-free applications |

Vibration Resistance | Excellent | Even higher pull-out force, superior performance |

Initial Cost | Typically lower | Can be slightly higher, but offset by labor savings |

Key Advantage | Mature, reliable technology | Unmatched installation speed and efficiency |

What tool can be used for spring terminal?

You must use a standard, flat-blade (slotted) screwdriver.

Why can't I use a Phillips (cross-head) screwdriver? The tip of a Phillips screwdriver is pointed and designed to cam out under pressure. This means it can slip out of the operating slot easily, not applying enough force to open the spring fully. More dangerously, it can slip and damage the spring mechanism or the surrounding plastic housing, irreparably breaking the terminal. The width and thickness of the screwdriver blade must match the terminal's operating slot. A blade that is too small will not effectively transfer force and may not open the spring completely, preventing a proper connection. A blade that is too large simply won't fit. Always refer to the manufacturer's specifications for the recommended tool size.

Every terminal is designed for a specific range of wire gauges (12 AWG to 24 AWG). This information is always printed on the device's housing. Attempting to use a wire that is too large will prevent the spring from closing properly, creating a dangerous, high-resistance connection. A wire that is too small may not be gripped securely enough.

FAQ

A:Select spring clamp terminals with a secondary locking mechanism (WAGO 221 series).Verify vibration resistance certification (compliant with IEC 61373 standard).Request a 1000-cycle insertion and withdrawal test report.

Q: Are push-in terminals reusable with many times?

A: Yes of course, both push-in terminals and spring-loaded terminals are designed for multiple uses. They can be opened with a tool to insert or remove wires hundreds of times without losing their clamping force, making them perfect for applications that require circuit changes or troubleshooting.

Q: Do I have to worry about the footprint when switching from spring-loaded to push-in?

A: Typically, no. For many devices, the external dimensions and footprint are identical between models with different connection technologies. This allows for a direct replacement without modifying the DIN rail or control cabinet layout.

A: Yes , first ,as we know is phoenix, wago ,Dinkle , degson, KEFA ,Shanye etc

You can choose that brand according to your actual requests.

A: we can supply free samples for you test in short -delivery time.

A:usually , we have stock for some hot sale models in your market ,so ,you no need to worry about anything!

A: Of course yes,we have our own powerful team for R&D , and production time is very soon . you just supply us datesheet or sample is enough.

A:usually ,we do 100% T/T prepayment with new customers, but after you placed 3 times order to us , we can negotiate patment terms.

Conclusion

In comparison with spring-loaded terminals, push-in terminals are not only easier to handle, but also offer significant time and cost advantages over the entire life cycle of a system—as a result, any additional costs for devices using this kind of connection technology very quickly pay for themselves. More information can be found in the webiste:www.cnsyelectronics.com

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected