- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 88 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.

Content

Terminal blocks ,are modular, insulated electrical connectors designed to secure and connect two or more wires together. They provide a safe, organized, and reliable way to manage complex electrical circuits, facilitating power distribution, signal routing, and control wiring. Essentially, they serve as a central hub where multiple wires can be easily connected, disconnected, and maintained without the need for soldering or direct splicing.

Key characteristics include:

· Modular Design: They can be assembled side-by-side on a DIN rail to create banks of connections.

· Insulation: The housing prevents accidental contact between conductors and provides protection against electrical shock.

· Clamping Mechanisms: Wires are secured using various methods, such as screws, springs, or push-in designs, offering different levels of ease of use and vibration resistance.

· Variety of Types: Available in numerous configurations, including feed-through, grounding, disconnect, and multi-level, to suit diverse application needs.

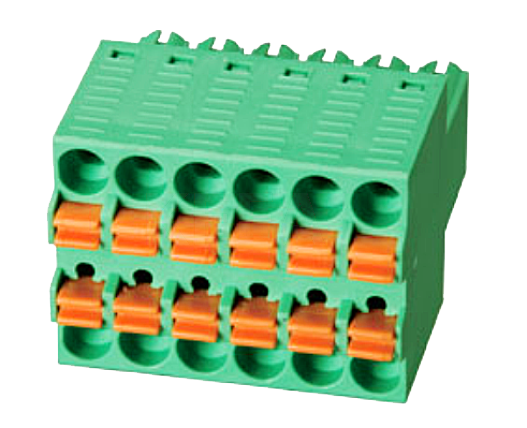

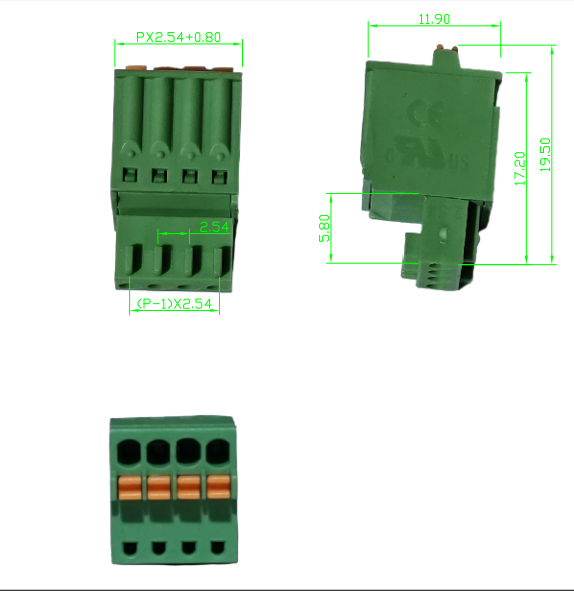

Plug-in series terminal blocks have two parts plugged and connected. One part presses the wire into place and then plugs into the other part. This part is soldered to the PCB board. This anti-vibration design ensures a long-term airtight connection and the reliability of the finished product. The sockets can add assembly lugs on both ends, primarily protecting the tabs and preventing poor alignment. The socket design also ensures that the socket will fit properly into the female body.

The sockets can also have assembly and locking fasteners. The assembly fasteners provide a more secure fixing to the PCB board. The locking snap position can lock the master and socket after installation. A variety of socket designs can match the different insertion methods of the masters. For example: horizontal, vertical, or inclined to the PCB, etc. Different methods can be selected according to customer requirements. Both metric and standard wire gauges are available.

It is suitable for the power supply equipment, automotive industry, LED lighting, computer room equipment, home appliances, security equipment, industrial control equipment, special appliances, etc.

It is the most cost-effective form of existing wiring technology.

It is suitable for building electrical, industrial control equipment, solar photovoltaic, automotive industry, LED lighting, wind power generation, instrumentation, medical equipment, etc.

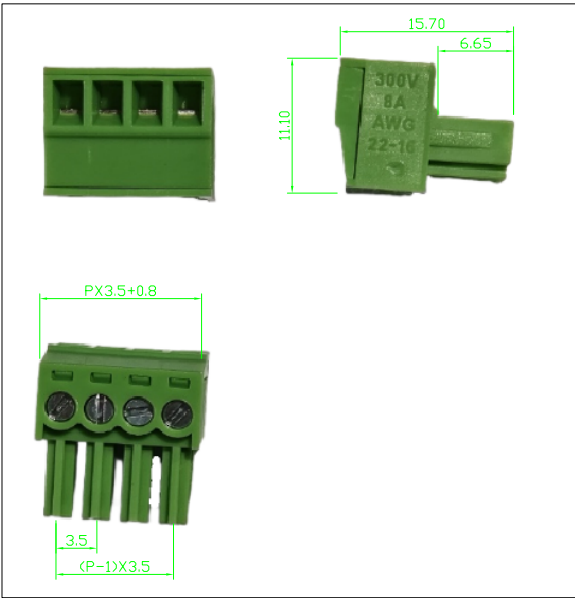

European Series of the Terminal Block

European Series of the Terminal Block Fence-type Series Terminal Block

Fence-type Series Terminal Block

Fence -type/barrier type terminal block can achieve safe, reliable, and effective connections. Especially in the high current, high voltage use of the environment more widely.

It is suitable for electrical control and distribution systems, industrial automation systems, power electronics, ship distribution systems, highway and bridge lighting systems, security monitoring systems, medical equipment, etc. Such as surgical light dimmers, respirators, distribution control panels in ship cabins, load centers, and integrated control systems, and other equipment.

The spring-type terminal block is a new terminal block using a spring device. Applicable to the world electrical and electronic engineering industry. Such as lighting, elevator lift control, instrumentation, power, chemical, and automotive power.

It is suitable for electronic equipment, industrial automation, robotic systems, energy and power systems, automotive electronics, LED lighting, billboards and other outdoor lighting, fire alarm, and security systems.

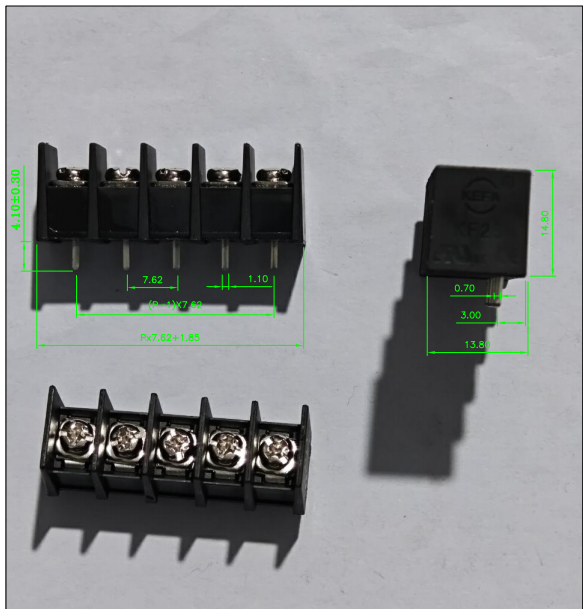

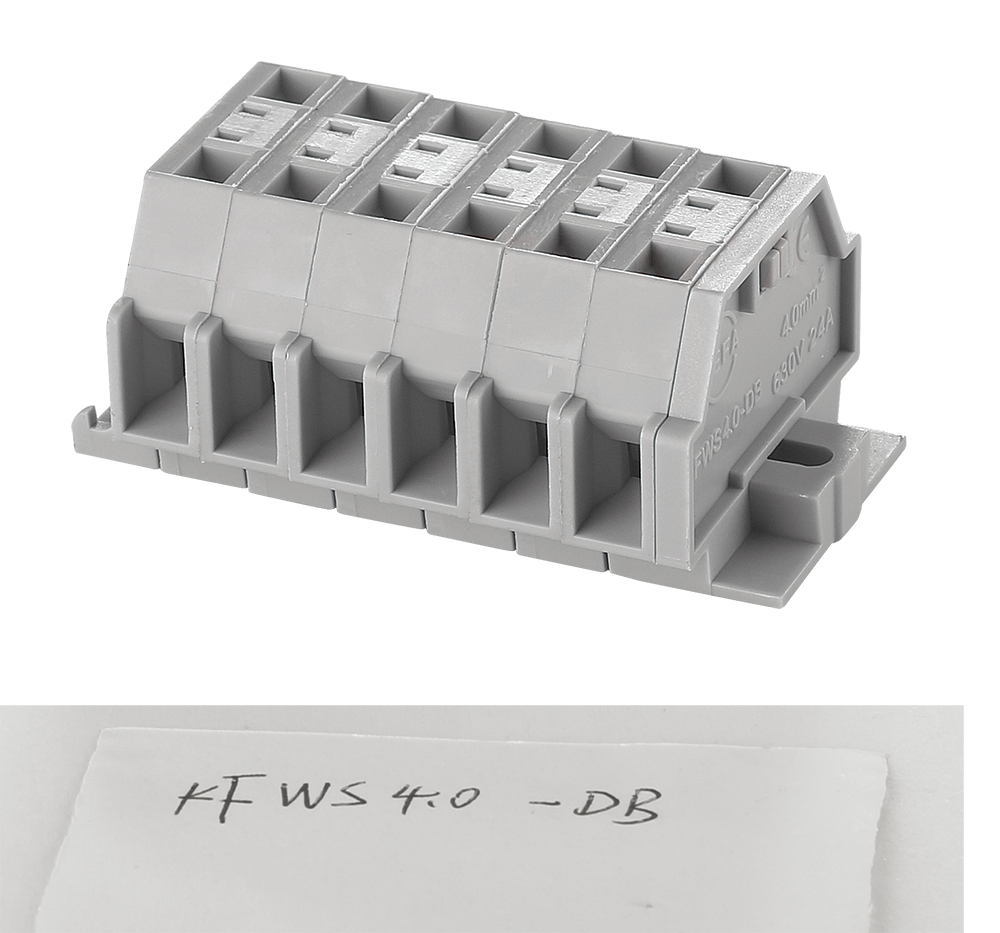

Rail-mounted terminal block adopts reliable threaded connection technology, electronic tolerance break technology, and the latest electrical connection technology.

It is widely used in power electronics, communication, electrical control, power supply, etc.

The ground terminal block is used to ground connections within an industrial control panel. It can also ground the terminal block itself to the mounting or DIN rail. These terminal blocks have a metal connection from the wire termination to the bottom of the block where it clamps into the panel. This eliminates the need to run a wire to the main ground connection.

The selection of terminal block materials directly affects the overall product performance. Taking plastic materials as an example: if the design is based on UL94 V-0 flame retardancy standards, it is crucial to carefully review whether the technical parameters in the material property datasheets of various suppliers can meet the product standards, such as impact withstand voltage and aging resistance tests.

For metal materials, the selection of the TP (Terminal Plate) contact spring material is particularly critical. This contact spring must meet both certain conductivity (current-carrying) requirements and possess specific elastic properties, which presents significant challenges for our engineers in material selection. Precisely in this aspect lies the current trend pursued by connector manufacturers in elastic components, with many metal material producers making dedicated efforts in this field.

Conductivity directly affects temperature rise and contact resistance, while elastic performance is related to the material's chemical composition, elastic modulus, hardness, and tensile strength. The elastic modulus should be calculated using the fourth strength theory formula from material mechanics.

The higher the material's conductivity, the lower the contact resistance and consequently the lower the temperature rise. The insertion/extraction force follows a quadratic curve relationship with contact resistance. Contact resistance mainly consists of: constriction resistance, film resistance, and bulk resistance (the conductor's inherent resistance). Among these, film resistance accounts for 70-80% of the total resistance and is the primary factor affecting connector lifespan, thus deserving full attention.

For example, comparing gold-plated and silver-plated terminals: although silver has higher conductivity than gold, its chemical stability is inferior, resulting in significantly higher film resistance than gold plating. Therefore, understanding these relationships provides guiding significance for our material selection and serves as a prerequisite for product design.

Shanghai Shanye Electronics(KEFA ELECTRONICS’s agent) found in 2017 year is a technology-based supplyer, specialized in terminal blocks, connectors,waterproof.With many years' development, shanye company owns many product line,which can meet different customers’s requests. KF136HT is high current terminal block, the nominal cross section is 16 mm² . We could produce from 2P to 24P. The connection method is screw connection with tension sleeve Of positions .This one can be replaced with Phoenix' 1774137 type.

Other terminal block supplyers also great . such as Phoenix, Wago,Dinkle, degson,etc,phoenix brand is well known in the world with so many years,they have more kinds of terminal block for choices. Quality is very good , but price is much higher, Wago brand is nearly from phoenix, their main goal market and customers are different ,Dinkle company located in taiwan, also developed with some years,as customer, you can choose the supplier in which your need and suit ,compare with quality ,price,service and so on.

Inserting a wire into a terminal block correctly is essential . while seemingly simple, terminal block wiring requires attention to detail to prevent loose connections, electrical faults, and potential safety hazards.Firstly, prepare the right wire. For screw-type terminal blocks, use the correct size screwdriver to loosen the screw sufficiently, opening the internal clamping plate or jaw. If it’s a spring-clamp or push-in type, activate the release lever or push button to open the clamping point. Make sure the opening is wide enough to easily insert the prepared wire without forcing it.Finally, gently tug on the inserted wire to ensure it is securely held within the terminal block and cannot be easily pulled out. Visually inspect the connection to confirm that no bare wire is exposed beyond the block’s body and that the insulation is properly seated against the terminal block. This verification step is crucial for preventing shorts and ensuring long-term reliability

Terminal Block Structural Design &Technical Details and Solutions

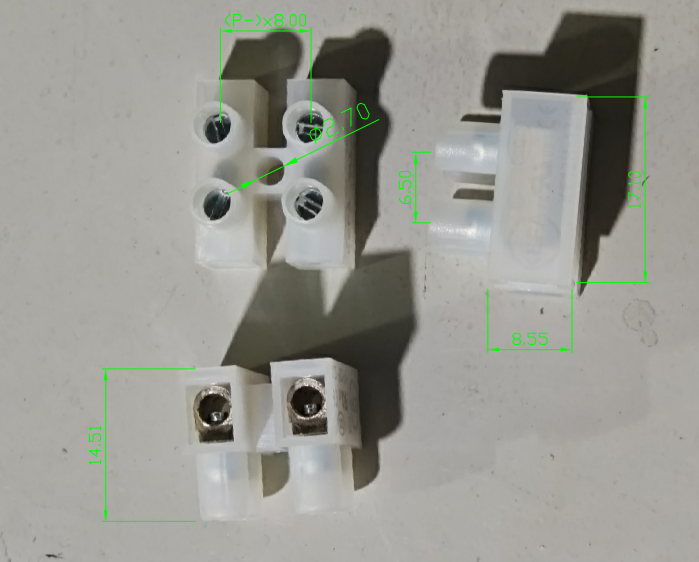

The structural design of terminal blocks is critical for performance and reliability. Based on our hands-on experience, each product series has unique requirements that must be addressed through careful engineering. Key design considerations include:Screw Retention - Preventing screws from loosening or falling out。Spliced Product Profiles - Curved front/rear designs for multi-piece assemblies。Long-Span Deformation - Minimizing bending in extended terminal blocks。Wall Thickness Control - Avoiding shrinkage and warpage from uneven material distribution。Screw Anti-Drop Methods。We primarily use four approaches:Three-Rib Design - Internal ribs grip the screw threads。Crimped Collar - Metal band compresses around the screw。Necked Orifice (Most Common) - Precision-sized opening holds screw securely。Stamped Retention - Formed metal tabs prevent screw movement。Note: While necked orifice is theoretically less common due to manufacturing challenges, it remains our preferred solution for most applications (using PA66 plastic).Necked Orifice Specifications (M3 Screw Example)。Actual M3 Screw Diameter: 2.90mm。Optimal Orifice Dimensions:Inner Diameter: 2.5–2.6mm。Wall Thickness: 0.4–0.5mm。Critical Feature: The screw must have a smooth shank section slightly smaller than the orifice to allow proper threading.Production Adjustment: Injection molding parameters must be fine-tuned for consistency.

Conclusion

Wiring a terminal block correctly is essential for ensuring safe and reliable electrical connections. By following the proper steps—from selecting the right wire and preparing it accurately to securely inserting it into the terminal—you create a robust and efficient electrical pathway.

For all your wholesale terminal block needs, ensuring quality and variety, please contact us. We supply a comprehensive range to meet diverse industrial and commercial requirements.

FAQ

A: Consider these factors:Current rating must exceed your circuit's maximum current)Voltage rating must exceed your system voltage.

Wire gauge .Environmental conditions (humidity, temperature, vibration

Connection type (screw,pluggable type,barrier type,Din rail, spring clamp, or push-in)

A: Only if:The terminal block is specifically designed for multiple wires.The combined wire gauge doesn't exceed the terminal's capacity.Local electrical codes permit it

A: Check for:No visible bare wire outside the terminal.Wire cannot be pulled out with gentle tugging.No movement at the connection point.Screws are tight but not over-torqued

A: Regular maintenance includes:Annual visual inspection for corrosion or damage.Checking tightness of screw terminals .Cleaning dust/debris from terminal blocks.Monitoring for signs of overheating

A: Ferrules are recommended when:Using stranded wires with screw terminals.Working in high-vibration environments

A: Look for these signs:Intermittent power or signal loss.Visible arcing or sparking.Discoloration or melting plastic.Flickering lights or equipment malfunction.

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected