- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 88 Author: Site Editor Publish Time: 2025-05-08 Origin: Site

Terminal blocks are essential electronic components in industry systems, providing secure and reliable connections between wires and circuits. As modular, insulated devices, they simplify wiring processes while ensuring safety and efficiency across industries. This comprehensive guide explores five major terminal block types—plug-in, spring-clamp, screw-type, barrier, and SMT—detailing their unique advantages, structural characteristics, and ideal applications.

Modern electrical systems demand connection solutions that balance performance with practicality. Whether in industrial control panels, automotive electronics, or consumer devices, selecting the proper terminal block significantly impacts system reliability, maintenance costs, and space utilization. We'll analyze each variant's technical specifications, including current ratings, installation methods, and environmental resilience, empowering engineers to make informed terminal block electrical choices.

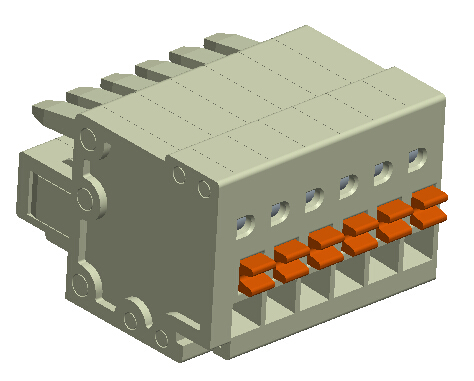

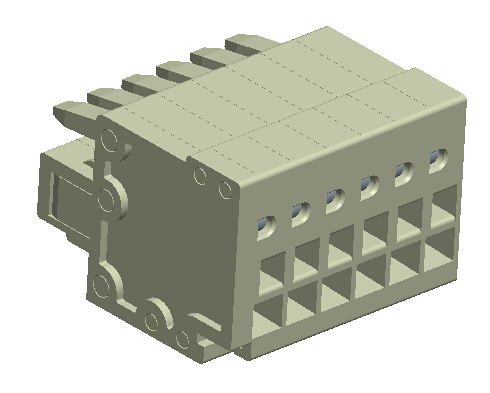

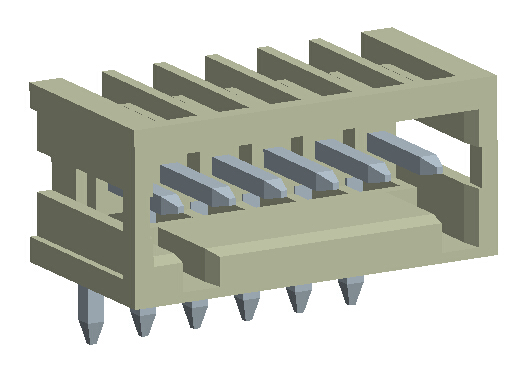

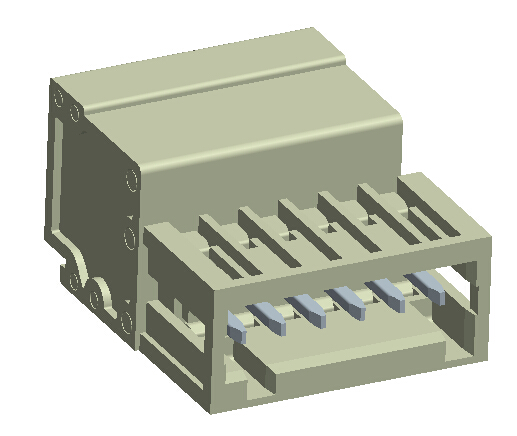

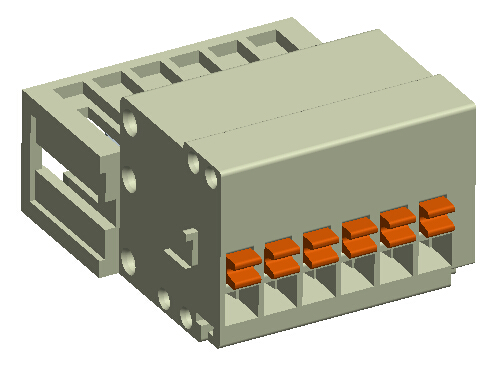

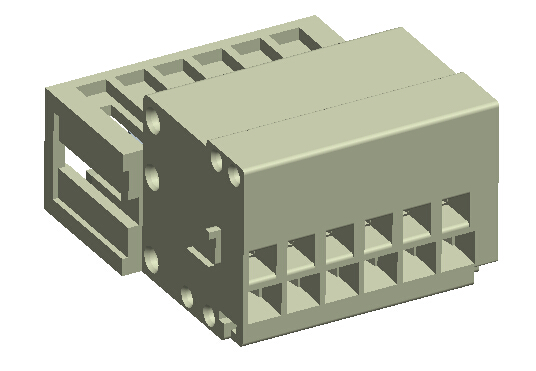

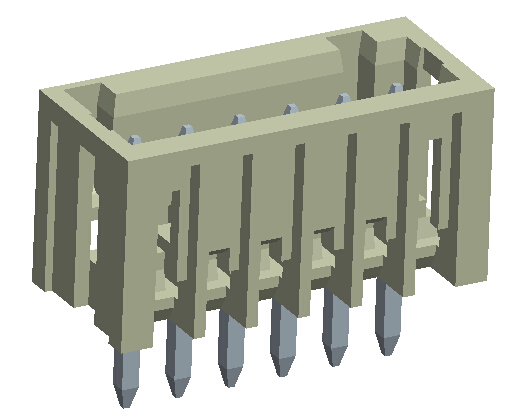

Plug-in terminal blocks (also called connector terminal blocks) feature a two-part construction—a male header soldered to the PCB and a removable female connector that houses wire terminations. This separable interface enables tool-free disconnection for maintenance or circuit modifications without desoldering. The design incorporates:

Dual-component architecture for modular field servicing 1

Four-sided solder pins that increase PCB contact area by 30% compared to round pins

Tapered pin tips facilitating smooth board insertion during assembly

Independent clamping mechanism isolating mechanical stress from solder joints,Performance Benefits in Real Applications

Industries requiring frequent circuit access benefit substantially from plug-in terminal blocks. Their advantages include:

High-density connections: Accommodate 4-24 AWG wires in compact footprints ideal for control panels

Vibration resistance: Locking clips prevent accidental disengagement in mobile equipment

Visual verification: Transparent housings enable quick inspection of wire seating

Thermal management: Integrated air channels dissipate heat from high-current paths

A 2023 study by Electrical Safety Foundation International (ESFI) found plug-in systems reduced industrial panel wiring errors by 42% compared to hardwired alternatives. Their quick-connect capability makes them preferred solutions for:

Factory automation I/O modules

Renewable energy combiner boxes

Transportation vehicle electrical systems

Spring-clamp terminal blocks utilize precision-engineered stainless steel springs to maintain constant pressure on inserted conductors. This technology eliminates screw-tightening while providing:

Self-adjusting tension accommodating wire sizes from 0.14-4mm² (30-12 AWG)

Gas-tight connections preventing oxidation at contact points

UL94 V-0 rated housings meeting stringent flame resistance standards 2

The spring's memory alloy construction ensures consistent clamping force across temperature fluctuations from -40°C to +105°C—a critical feature for outdoor or thermally challenging environments.

Comparative studies reveal spring-clamp terminals deliver measurable efficiency gains:

80% faster installation versus screw-type terminals

50% space savings in control cabinet layouts

Zero maintenance requirements over product lifetime

These benefits stem from the tool-free insertion process and elimination of periodic torque checks needed for screw connections. Major applications include:

Building automation systems

LED lighting arrays

Instrumentation clusters

Screw-type terminals dominate high-power applications through robust metallic components:

Copper alloy contact bodies with 95% IACS conductivity

Hardened steel fasteners generating up to 500N clamping force

Anti-rotation thread designs preventing vibrational loosening

Their ability to terminate conductors up to 240mm² while carrying 400A currents remains unmatched by alternative technologies 3. The screw's mechanical advantage creates metallurgical bonding between wire strands, forming reliable connections even with:

Multi-stranded cables

Fine-gauge wires

Aluminum conductors

Industrial variants incorporate specialized features:

Dual-level entry points simplifying wire routing

Test ports enabling circuit verification under load

Bridge slots for common bus configurations

These characteristics make screw terminals indispensable for:

Motor control centers

Power distribution panels

Heavy machinery wiring

barrier strip terminal block employ a unique open-frame design with:

Isolated metal partitions preventing accidental contact

Deep wire channels containing stripped conductors

Dual-screw clamping for positive retention

The visible separation between phases simplifies inspection and meets NEC requirements for voltage isolation. Their construction handles:

600V AC/DC systems

4-350MCM conductors

Harsh environmental conditions

Unlike enclosed terminals, barrier types permit:

Mid-span taps without disassembling runs

Custom insulator configurations

Visual polarity confirmation

These traits prove valuable in:

Commercial building wiring

Agricultural equipment

Marine electrical systems

Surface-mount technology (SMT) terminals revolutionize board-level connections through:

50% size reduction versus through-hole models

Automated placement compatibility

High-frequency signal integrity

Their leadless design minimizes parasitic effects, supporting data rates exceeding 1Gbps. Advanced versions feature:

Embedded fuses for circuit protection

Stackable configurations saving board space

Thermal vias dissipating joule heating

SMT terminals enable:

30-50% lower assembly costs

Higher component density

Improved shock/vibration resistance

These attributes drive adoption in:

Telecom infrastructure

Automotive ECUs

Portable medical devices

| Type | Current Range | Wire Size | Tool Requirement | Reusability |

|---|---|---|---|---|

| Plug-In | 5-30A | 24-4 AWG | None | High |

| Spring-Clamp | 1-20A | 30-12 AWG | None | Medium |

| Screw-Type | 10-400A | 28-350 MCM | Screwdriver | High |

| Barrier | 15-100A | 22-250 MCM | Screwdriver | High |

| SMT | 0.5-10A | 30-18 AWG | Soldering Iron | Low |

Industrial Control Panels: Screw-type for power, spring-clamp for signals

Automotive Electronics: SMT for ECUs, plug-in for harness interfaces

Building Wiring: Barrier for mains, spring-clamp for controls

Consumer Devices: SMT for compactness, plug-in for serviceability

The terminal block market evolves through:

Smart terminals with integrated sensors

Hybrid connector-block systems

Environmentally-conscious materials

These innovations address demands for:

Predictive maintenance capabilities

Modular system architectures

Sustainable manufacturing

Understanding terminal block varieties empowers optimal selection. While screw-types suit brute-force power applications, SMT versions enable microelectronics integration. Spring-clamp models excel where speed matters, while plug-in designs facilitate servicing. Barrier terminals remain the high-voltage specialist. By aligning technical capabilities with project requirements, engineers can build safer, more efficient electrical systems.

For further technical specifications, consult industry standards from:

International Electrotechnical Commission (IEC 60947-7-1)

Underwriters Laboratories (UL 1059)

Institute of Electrical and Electronics Engineers (IEEE 837)

At last , welcome to click here to get more choices !

https://www.cnsyelectronics.com/Pluggable-Terminal-Blocks-pl49641887.html

https://www.cnsyelectronics.com/European-Terminal-Blocks-pl40641887.html

https://www.cnsyelectronics.com/Barrier-Terminal-Blocks-pl41641887.html

https://www.cnsyelectronics.com/SMT-Terminal-Block-pl42641887.html

https://www.cnsyelectronics.com/Transformer-Terminal-Blocks-pl47277787.html

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected