- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 300 Author: Site Editor Publish Time: 2025-05-28 Origin: Site

How to Install Terminal Blocks Safely

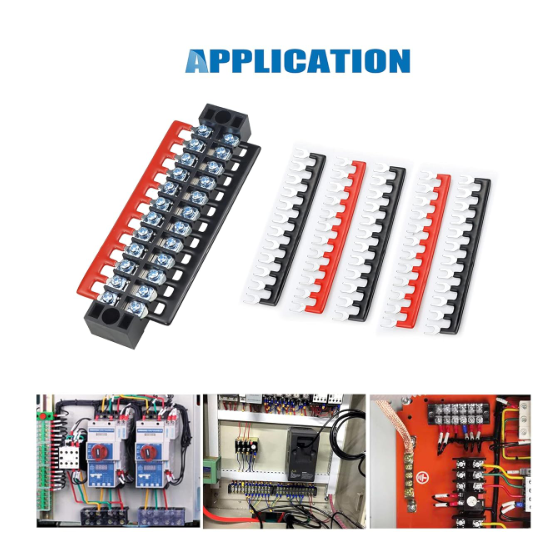

Terminal Block plays a very important role in electronics components and industry , lighting, PLC control systems ,and our daily life,such as Home appliance etc.So ,Proper terminal block installation is critical for electrical safety, system reliability, and compliance with international standards. Incorrectly installed terminal block screws or poorly sealed waterproof terminal block systems can cause arc faults, fires, and equipment damage. This comprehensive guide demonstrates professional installation techniques for common terminal types including 3 pole terminal block, panel mount terminal block, and screw terminal barrier block, referencing IEC 60947-7-1 safety standards.

1.1 Pre-Installation Safety Preparations Required Tools & Materials Insulated screwdrivers (torque-controlled for terminal block screws)

Wire strippers with depth gauge (avoid nicking conductors)

Multimeter for continuity verification

Dielectric grease for waterproof terminal block seals

Anti-vibration washers for industrial environments

Thermal camera for post-installation inspection

1.2 Safety Protocols De-energize circuits and verify with voltage tester

Wear OSHA-compliant PPE: Class 00 rubber gloves + arc-flash face shield

Review schematics: Confirm voltage/current ratings match terminal power block specifications

Regulatory Reference: OSHA Electrical Safety Standards

1. Installation Procedures by Terminal Type 2.1 Screw Terminal Blocks (e.g., Entrelec Terminal Block) Step 1: Torque Application

Use calibrated torque driver (see table below)

Avoid overtightening to prevent thread stripping

Screw Size Recommended Torque Max Force M3 (common in green terminal block) 0.5 N·m 0.8 N·m M4 (for terminal power block) 0.8 N·m 1.2 N·m Step 2: Conductor Preparation

Strip 8-10mm insulation (7mm for Molex terminal block)

Twist stranded wires clockwise before insertion

Critical: Ensure no stray strands outside clamp zone

2.2 Waterproof Terminal Blocks (IP67/IP68) Step 1: Seal Activation

Apply silicone grease to O-ring (terminal block cover gasket)

Hand-tighten housing before final torque

Step 2: Cable Gland Integration

Use dual-compression glands for 360° sealing

Strain relief must support 3x cable weight

Standard Reference: IEC 60529 IP Rating Guide

2.3 3 Pole Terminal Blocks (3-Phase Systems) Step 1: Phasing Verification

Label phases L1/L2/L3 per IEC 60446 color code:

Brown (L1), Black (L2), Gray (L3)

Maintain 3mm minimum creepage distance

Step 2: Barrier Installation

Install partition plates between phases

Verify dielectric strength >4kV (per IEC 60664-1)

1. Specialized Mounting Techniques 3.1 Panel Mount Terminal Block Installation Reinforcement: Use backing plates for >10A circuits

Grounding: Bond metallic panel mount terminal block to chassis

Clearance: Maintain 25mm ventilation space above/below

3.2 DIN Rail Mounting (e.g., Entrelec Terminal Block) Snap rail per EN 60715

Slide blocks with uniform spacing

Install end stoppers to prevent creep

1. Critical Safety Accessories 4.1 Terminal Block Cover Selection Cover Type Protection Level Best For Transparent PVC IP20 Indoor control panels Polycarbonate IP66 Waterproof terminal block outdoor use Vented metal Thermal management High-current terminal power block 4.2 Safety Labeling Requirements Apply warning labels within 150mm of screw terminal barrier block:

"DANGER: Live Parts - Disconnect Power Before Servicing"

Torque specifications

Circuit identification

Compliance Resource: ANSI Z535 Safety Sign Standards

1. Hazard Prevention Strategies 5.1 Arc Flash Mitigation Use green terminal block for grounding (IEC 60417-5019)

Install arc containment shields on >120A terminal power block

Apply phase barriers in 3 pole terminal block systems

5.2 Vibration Protection Apply thread-locker to terminal block screws

Install spring washers on panel mount terminal block

Use Molex terminal block with PosiLock retention

1. Verification & Testing 6.1 Post-Installation Checklist Continuity test (resistance <0.5Ω between points)

Insulation resistance test (>100MΩ at 500VDC)

Thermal scan under load (ΔT <30°C vs ambient)

Vibration test (5-500Hz sweep for 30min)

6.2 Maintenance Schedule Interval Action Monthly Visual inspection (corrosion/looseness) Annually Re-torque terminal block screws to spec 5 Years Full dielectric strength validation 7. Real-World Failure Case Studies Case 1: Water Intrusion in Solar Farm Issue: Unsealed waterproof terminal block caused DC arcing

Solution: Installed IP68 covers + annual dielectric testing

Case 2: Vibration-Induced Failure Issue: Loose terminal block screws in CNC machine

Solution: Switched to spring-cage Molex terminal block

How should we do to deal with failure when wiring connection

I. Emergency Response (Critical 30-Minute Window)

1. Safety Isolation

Power Disconnection:

De-energize upstream power (dual verification via circuit breaker + disconnect switch)

Hang "DANGER: Do Not Energize" tags (per OSHA 1910.333)

Capacitor Discharge:

Use discharge rods for capacitor circuits (wait 5τ time constant for systems >1kV)

1. Failure Documentation

Failure Type Critical Observations Forensic Tools Overheating/Burning Carbonized insulation, metal melting Infrared thermography (archive thermal profile) Poor Contact Oxidation (verdigris/dark spots) Macro photography of contact surface Insulation Failure Tracking marks, carbonization paths 500V megger insulation resistance test Safety Standard: NFPA 70E Arc Flash Protection

II. 4-Step Failure Diagnosis

1. Contact Resistance Analysis

Acceptance Criteria:

Signal terminals: ≤ 10mΩ

Power terminals (e.g., 3-pole terminal block): ≤ 3mΩ

Tools:

Micro-ohmmeter (Fluke 1587)

Anomaly Threshold: >15% resistance fluctuation or exceedance

1. Mechanical Integrity Check

Screw Terminals (terminal block screws):

Thread damage (check with thread gauge)

Clamping force degradation (torque wrench verification: M3 screws ≥0.5N·m)

Spring Terminals (e.g., Molex terminal block):

Spring fatigue (feeler gauge detection: >0.2mm displacement = failure)

1. Environmental Compatibility

Waterproof Terminals (waterproof terminal block):

O-ring hardness check (Shore A >70 indicates aging)

IP rating validation (spray test per IEC 60529)

Chemical Corrosion:

EDX elemental analysis of corrosion products (e.g., sulfide-induced silver migration)

III. Type-Specific Repair Solutions

1. Screw Terminals (terminal block screws)

Failure Repair Solution Prohibited Actions Stripped threads Replace with Ni-plated stainless screw + threadlocker No re-tapping (compromises torque) Contact oxidation Polish + apply metal-particle conductive grease No sandpaper (leaves insulating residue) 2. Spring Terminals (e.g., Molex 188 series)

Spring failure: Replace spring module with specialized tool

Housing deformation: Full terminal replacement (non-repairable)

1. Insulation Repair (terminal block cover damage)

Temporary fix:

Clean + inject 3M Scotchcast 8+ resin

Permanent solution:

Replace with UL94 V-0 certified flame-retardant cover

IV. Preventive Upgrade Measures

1. Terminal Selection Upgrade

Failure Cause Upgrade Solution Standard Reference Overheating Tin-plated copper terminals (+30% current) IEC 61238-1 Class A Vibration loosening Push-in terminals (e.g., WAGO 221) EN 61373 Category 1 Chemical corrosion PTFE-sealed waterproof terminal block ISO 9227 C5-M rating 2. Smart Monitoring Integration

Temperature alerting:

Apply RFID temperature tags (e.g., PhaseIV OT-300)

Threshold: ΔT >15°C alarm

Connection resistance monitoring:

Install wireless sensor terminals (e.g., Weidmüller SmartEye)

Technical White Paper: Smart Terminal Monitoring Solutions

V. Authoritative Failure Analysis Tools

1. Root Cause Analysis (RCA)

Verify load profile

1. Laboratory Testing

Thermal analysis:

DSC for insulation material glass transition temp (Tg)

Mechanical endurance:

Insertion/extraction tests (IEC 60512 - 100 cycles)

VI. Standards-Compliant Disposition Process Incident Reporting:

Submit preliminary report to insurer within 24h (with thermograms/resistance data)

Technical Archiving:

Create "black box" record for failed terminals (retain ≥10 years)

Procedure Updates:

Revise maintenance protocols per IEC 60947-7-1:2020 Clause 9

Case Study: Data Center Terminal Overheating Background: 3-pole terminal block reached 98°C in 200A distribution cabinet

Diagnosis:

Phase C resistance: 12mΩ via micro-ohmmeter (normal ≤3mΩ)

IR imaging showed localized hotspot

Root Cause:

Aluminum conductor creep relaxation due to missing antioxidant

Solution:

Replaced with silver-plated copper terminals (+40% current)

Installed wireless temperature monitors

Revised installation protocol requiring antioxidant paste

Ultimate Safety Principle:

For failures involving high-voltage terminals (>1000V) or explosive atmospheres, only IECEx-certified technicians may intervene! Certification Verification: IECEx Certified Equipment Database

Conclusion: 5 Non-Negotiable Safety Rules Always de-energize before touching screw terminal barrier block

Torque precisely - Never guess terminal block screws tightness

Ground religiously - Use green terminal block for safety earth

Seal aggressively - Over-engineer waterproof terminal block protection

Document meticulously - Label every 3 pole terminal block phase

Industry Standards Hub: IEC 60947-7-1 Terminal Block Requirements

FAQ: Q:Can I reuse screw-type terminal blocks?

A: yes, Only if contacts show no pitting/arcing. Replace Entrelec terminal block after 3 re-torque cycles.

Q: How to protect aluminum conductors?

A: Use antioxidant paste and dual-force screw terminal barrier block.

Q: What's the lifespan of waterproof terminal blocks?

A: 15-20 years if seals are maintained. Inspect terminal block cover gaskets annually.

Q: Are green terminal blocks mandatory?

A: not mandatory , but green terminal blocks are very used normally in electronic components.

Q: When to choose Molex vs Entrelec terminal blocks?

A: Molex for vibration environments, Entrelec for high-density power distribution.

Our mission:

Shanghai Shanye Electronic Co., Ltd. established in 2017, is a well-known manufacturer of high-quality Terminal Blocks and Connectors in Asia. The company integrates R&D, production, and after-sales services, offering over 10,000 product varieties widely used in industrial control systems, rail transit, security, elevators, and lighting industries.Shanye Electronics adheres to strict quality standards, holding ISO 9001, ISO 14001, and IATF 16949 certifications.etc. our mission is try to help every customer find suit and competitive terminal block , satisfy customers 's customized requests in shortest time !

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected