- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 98 Author: Site Editor Publish Time: 2025-05-04 Origin: Site

Terminal Block Manufacturing: From Raw Materials to Finished Product

Terminal Block Manufacturing: From Raw Materials to Finished Product

Introduction

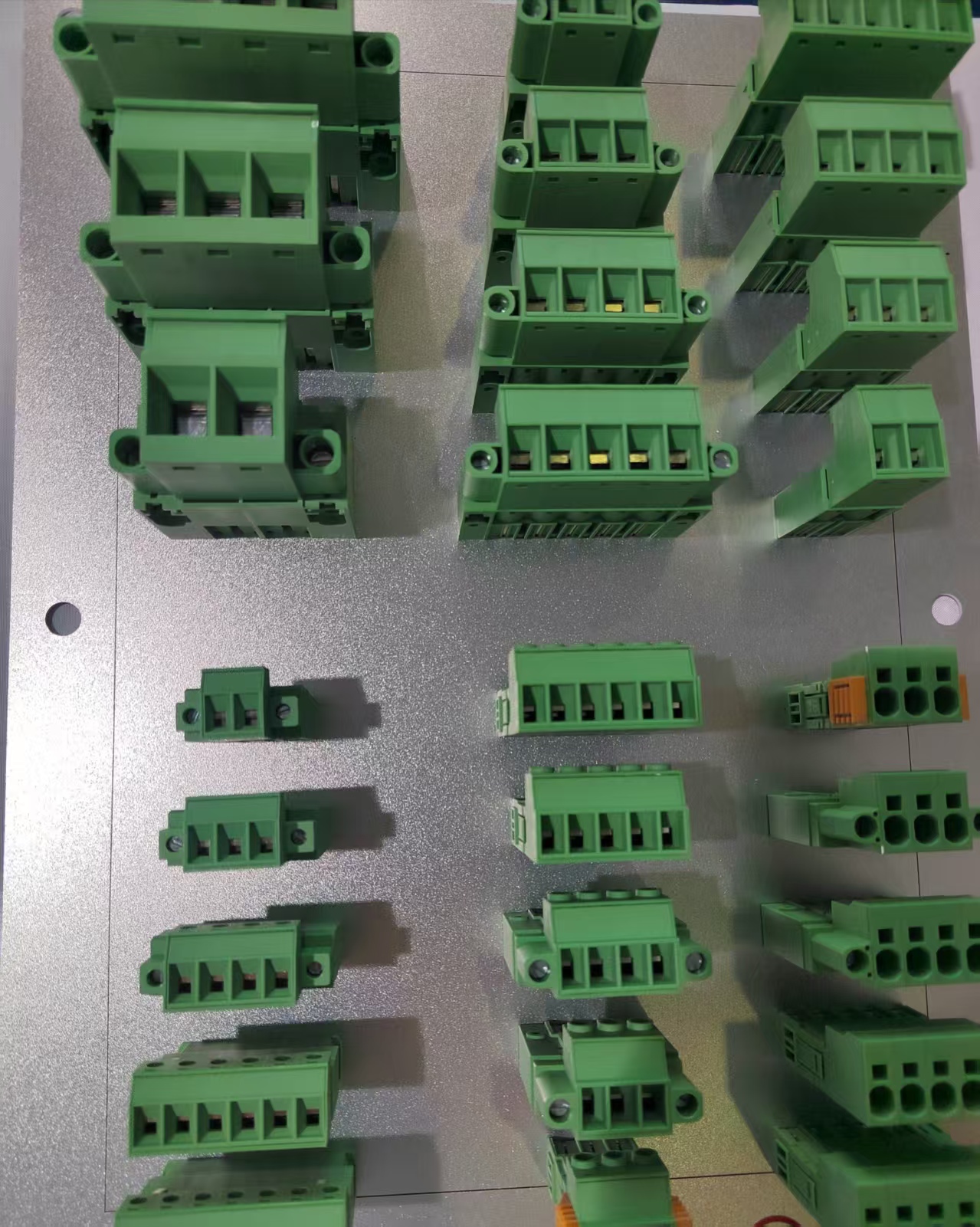

Terminal blocks are essential components in electrical systems, ensuring secure and reliable connections. Their manufacturing process involves precision engineering, material science, and rigorous quality control. This article explores the step-by-step production of terminal blocks, covering key materials, manufacturing techniques, and quality testing to ensure durability and performance.

H1: Key Materials in Terminal Block Production

The performance of a terminal block depends heavily on the materials used.

Manufacturers select materials based on electrical conductivity, mechanical strength, and environmental resistance.

H2: Insulating Materials The outer housing of a terminal block must be non-conductive, heat-resistant, and durable. Common materials include:

Polyethylene (PE)

Advantages: Low cost, good moisture resistance.

Applications: Low-voltage terminal blocks.

Polypropylene (PP)

Advantages: Higher heat resistance (up to 100°C) and better mechanical strength.

Applications: Industrial and automotive terminal blocks.

Polyamide (PA/Nylon)

Advantages: Excellent flame retardancy and high-temperature resistance.

Applications: High-performance and fire-safety-critical applications.

H2: Conductive Materials The internal conductive parts must ensure low resistance and corrosion resistance.

Copper (Cu)

Advantages: High conductivity, easy to machine.

Standard Alloys: Brass (Cu-Zn), Phosphor Bronze (Cu-Sn-P).

Aluminum (Al)

Advantages: Lightweight, cost-effective.

Limitations: Lower conductivity than copper, prone to oxidation.

Plating & Coatings

Tin (Sn) Plating: Prevents oxidation and improves solderability.

Gold (Au) Plating: Used in high-reliability applications (e.g., aerospace).

H1: Precision Manufacturing Process

H2: Step 1 – Mold Design & Injection Molding Mold Design:

CAD/CAM software designs molds for plastic housings.

Precision tooling ensures tight tolerances (±0.05mm).

Injection Molding:

Plastic pellets are melted and injected into molds.

Cooling and ejection produce the final housing.

H2: Step 2 – Metal Stamping & Forming Stamping Process:

Copper/aluminum sheets are punched into precise shapes.

Progressive dies allow multi-stage forming.

Bending & Assembly:

Metal parts are bent into final shapes (e.g., clamping plates).

Some designs require insert molding (metal parts embedded in plastic).

H2: Step 3 – Electroplating & Surface Treatment To enhance durability, conductive parts undergo:

Three-Layer Electroplating (Ni-Sn-Cu):

Nickel (Ni): Base layer for adhesion.

Copper (Cu): Enhances conductivity.

Tin (Sn): Prevents oxidation.

Alternative Coatings:

Silver (Ag): High conductivity for power terminals.

Gold (Au): Used in high-frequency applications.

H1: Quality Control & Testing Every terminal block undergoes strict testing to meet industry standards (UL, IEC, RoHS).

H2: Mechanical Strength Testing Pull-Out Force Test: This test measures wire retention strength (e.g., 50N minimum for industrial terminals).

Vibration & Shock Testing: Ensures stability in automotive/aerospace applications.

H2: Electrical Performance Testing Contact Resistance Test: Ensures low resistance (<5mΩ for high-current terminals).

Dielectric Strength Test: Checks insulation at high voltages (e.g., 2.5kV for 1 minute).

H2: Environmental & Durability Testing Temperature Cycling: This test exposes terminals to extreme heat/cold (-40°C to +125°C).

Salt Spray Test: Evaluates corrosion resistance (e.g., 500 hours for marine applications).

H1: Future Trends in Terminal Block

Manufacturing Smart Terminal Blocks: Integrated sensors for real-time monitoring.

Eco-Friendly Materials: Bio-based plastics, lead-free plating.

Additive Manufacturing (3D Printing): Rapid prototyping of custom designs.

Conclusion

Terminal block manufacturing is a highly engineered process, combining material science, precision machining, and stringent quality checks. From plastic injection molding to advanced electroplating, each step ensures reliability in demanding applications.

As technology evolves, more innovative, greener, and more efficient terminal blocks will continue to shape the future of electrical connectivity.

A terminal block is a compact, insulated base with metal contacts that lets you clamp, join, and distribute conductors without soldering. If you’ve ever routed power to a drive, brought sensor leads into a controller, or handed off field wiring to a PCB, you’ve used one. Understanding what is a term

As a Engineer ,It is very important to choose globally recognized premium terminal blocks .these manufacturersas below: Phoenix Contact, WAGO, Weidmüller, Eaton, Molex, Amphenol, Harting, and Shanye Electronics (subsidiary of Kefa Electronics). These industry leaders collectively dominate the $4.6

This article covers the technical features of spring-loaded and push-in terminals, and both the advantages and disadvantages of these technologies when it comes to installation practices, commissioning, footprint and authorisation for the North American market. Why do we need spring terminal block ?

Wiring a terminal block correctly is a fundamental skill in electrical work, ensuring safe and reliable connections. This article will help you to understand the essential steps, from preparing your wires to securing them properly within various terminal block types.ContentWhat are Terminal Blocks?R

What is terminal block ?terminal block, also known as a connection terminal, is a modular block used in electrical and electronics systems to connect and secure electrical wires or cables. It serves as a convenient and organized way to make electrical connections, whether for power distribution, sig

Terminal electronics is the key point at which a conductor from a electronic component, device or network comes to an end.Terminal may also refer to an electrical connector at this endpoint, acting as the reusable interface to a conductor and creating a point where external circuits can be connected